What is Abrasive Waterjet? Our Experience Before discussing our waterjet experience, it is important to remember that we have been a precision machine shop since 1982. We routinely hold tolerances of less than .0005"(.013mm), and we know how to inspect parts.

abrasive water jet machining

Abrasive waterjet cutting involves using an extremely fine jet of water travelling at high velocity, into which an abrasive material is mixed for cutting hard materials such as granite and titanium. This process makes a very fine cut into the material, known as a kerf.

In abrasive water jet machining a small stream of fine grained abrasive particles is mixed in suitable proportion, which is forced on a work piece surface through a nozzle. Material removal occurs due to erosion caused by the impact of abrasive particles on the work surface.

Precision abrasive jet machines can obtain about the same or higher tolerances than lasers (especially as thickness increases). Waterjets are safer. Maintenance on the abrasive jet nozzle is simpler than that of a laser, though probably just as frequent. After laser cutting After waterjet cutting Waterjets vs. EDM Waterjets are much faster than EDM.

Abrasive Flow Machining. Abrasive Flow Machining (AFM) is a secondary water jet machining process used to smooth, polish, radius, and remove cracks and burrs from hard to reach or internal surfaces of machinery, parts and products. It uses a polymer resin and abrasive materials, which are called media, in water under pressure to reach bends, cavities and edges.

Mechanical energy based nontraditional machining (NTM) processes directly utilize mechanical energy to gradually remove material from the workpiece primarily by erosion. Examples of such processes include abrasive jet machining (AJM), water jet machining (WJM), abrasive water jet machining (AWJM) and ultrasonic machining (USM).

Cutting Edge Water Jet Service is a job shop provider of abrasive waterjet cutting services for all domestic Industries, serving Chicago in the Midwest and the other national regions. CEWJS offers 60,000 and 90,000 psi conventional and dynamic abrasive waterjet cutting.

Ice jet machining is an important sustainable variant of abrasive water jet machining (AWJM) which ensures the environmentally friendly cutting, finishing, cleaning, and deburring of a variety of materials.

Abrasive water jet machining Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. info. about abrasive water jet machining

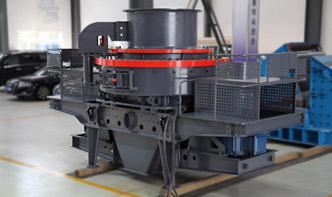

HEADstandard water jet cutting machine series. Threeaxis water cutting machine, composed of Xaxis, Yaxis, Zaxis coordinate system, in the highpressure water jet by adding abrasive, you can achieve the stone, metal, ceramics, glass and other hard material cutting,Ultrahigh pressure generator cutting capacity of up to 100mm.

One of the important manufacturing technologies is abrasive water jet (AWJ) machining, which is considered as a nonconventional machining process. Abrasive water jet machining depends on a highpressure of water provided by a pump on the orifice inside the cutting head where it can be converted into a high velocity jet.

The Abrasive Water Jet Machining equipment used consists of a high pressure pump Streamline SLV 50 Plus made by KMT that is fitted on a CNC cutting portal with an abrasive feeding system that varies the feed rate in the range of 100–10000 grams/min. Abrasive material used was Garnet sand.

Abrasive waterjet machining (AWJM) is one of the modern machining process for difficult to cut materials. It is an environment friendly and relatively inexpensive .

Hourly Cost to Run an Waterjet The Long Answer. Fact: The abrasive flow rate is determined by the size of your pump, not the manufacturer. Fact: You should plan on your ruby orifice lasting approx 40 hrs sales people may say 80 hrs. Fact: You should plan on a diamond orifice lasting approx 500 hrs sales people may say 1,000 hrs. Fact:...

These are environmentally green systems, using only a natural garnet, abrasive, and water in the abrasive water jet cutting process. Being your Ohio waterjet cutting service experts, we have three waterjets in Marysville, Ohio; all are 5axis water jets. The Omax 55100 has a Tiltajet taper and The Maxiem 1530 has an Ajet .

The abrasive water jet was applied to micro machining and fluid polishing of glass using stagnation generated under the jet nozzle. In order to finish a crackfree surface, the process should be controlled so that the abrasive particles flow horizontally and collide onto the surface at small impingement angles.

Advanced continuous fiberreinforced ceramic composite (CFCC) materials have been machined with abrasive water jet (AWJ) drilling and cutting processes. Cutting forces, surface microstructure, and retained tensile behaviors were evaluated using dynamometry, surface profilometry, scanning electron microscopy, and tensile testing, respectively.

High precision CNC water jet cutting machine is widely used in industrial applications like 3D waterjet cutting, custom metal stone cutting and glass cutting.

The most efficient abrasive for waterjet cutting available. GMA Garnet is one of the world's most efficient waterjet abrasives in terms of cutting speed, abrasive consumption and uninterrupted cutting. GMA garnet grains are amongst the hardest and toughest minerals known today.

This can be eliminated by using abrasive water jet machining. The abrasive powder cannot be reused because its cutting ability decrease and it may clog on orifice of the nozzle. Higher chance of stray cutting. Tapering may occur during drilling. AJM not suited for machining of soft material because the abrasive may get embedded in the work ...

Abrasive Waterjet Cutting Abrasive water jet cutting is a process using special tools capable of slicing into metal or other materials using a jet of water at a high velocity and pressure, or by using a mixture of water and an abrasive substance.

KMT Waterjet Systems For stone cutting, metal cutting, glass cutting, food cutting, water jet steel cutting. Speed, productivity and efficiency benefits of water jet cutting.

Abrasive Waterjet Machining Description: The cutter is commonly connected to a highpressure water pump, where the water is then ejected from the nozzle, cutting through the material by spraying it .

Waterjet cutting is the use of a special cutter the uses a high pressure jet stream of water to cut different materials. The extreme version of erosion which happens in nature, the waterjet cutter, often mixed with other abrasive particles, simply speeds up the process many times over. Advantages of Waterjet Cutting.