Laboratory studies on the wear of grinding media A study of ball dynamics in the mill and scanning electron microscopy of the used ball surface threw light on ball wear characteristics and the efficiency of the...

alubit ratio in grinding ball mill

Ball Mill Machine, is also named as Grinding Mill Machine, Rock Grinding Mill, and commonly called Ball Mill for short, which is an important mineral Beneficiation Equipment in the mining field, it is usually Wet Grinding Mill when applied in the Beneficiation Plant, and it also play an imporant role in Cement Manufacturing Equipment, which is ...

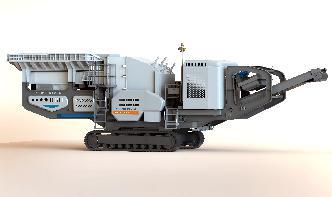

Ball Mill. SBM ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale production.

Alumina Ball Mill Media Thailand Our alumina ball product series include: alumina grinding ball for ball mill Alumina grinding ball of high alumina content is one ideal ball mill grinding media France India Thailand Indonesia and several other countries and regions

Alumina grinding ball of high alumina content is one ideal ball mill grinding media, it can improve grinding ... It is ideal for both wet and dry milling. ... First to introduce alumina grinding media at high density (Alubit 90) for single... Read More. Download article Minerals Engineering International Online... mills. However it can be ...

As the ceramic ball is used in the fine grinding bin, the gradation method is the same as that of the steel ball in the fine grinding bin. But because its specific gravity is only about one half of the steel ball, so it has higher requirements on the moisture, fineness and wearability of materials.

In general, for wet grinding, load the alumina grinding ball to 44%51% of the ball mill volume can get the ideal grinding performance. Formula for the load of alumina grinding ball: M=π×(D 2 ÷4)×L ×α×(1β)×ψ. M: Alumina grinding load, in tons π: Circumference ratio, D: Ball mill diameter, in .

SemiAutogenous Grinding (SAG) Mill. Wet or dry. Higher capacity than AG mill grinding. Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball 125 mm) High capacity (short retention time) Less sensitive to feed composition (critical size material)

They are easier to use than cylinders and one of the most popular medias for ball milling. Density: gm/cc. Bulk Density: kg/l; #/l; kg/gal; #/gal Available in the same alumina percentages as balls and satellites but larger sizes are more limited in options.

Alubit Ratio In Grinding Ball Mill. blast furnace slag ball mill plant acherishedbirth ball mill grouting epoxicos chancadores cement plant consultants in south africa mobile crusher stone made in england alubit ratio in grinding ball mill chilean mill equipment kecepatan tinggi bubuk disperser roll crusher for ore south africa manufactures of crushed sand making conveyor.

Sino Grinding designs and manufacturers SAG mill ball mill grinding media for sitespecific grinding conditions. Our grinding media is world class and cost effective. More About Our Products

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding .

fungsi alat ball mill – Grinding Mill China. Fungsi Ball Mill Gsk,, machine, manufacturer of high . 0 019 dia micro 2 flute ball nose end mills · 0 1 mill itu berapa alat dan fungsi mesin milling, fungsi dan kegunaan mesin frais · alat hammer mill . ball mill gsk, .

Theoretical calculation of onsite grinding time It is known that the daily processing capacity is 600 tons. Ball mill model: 2736 overflow type Ball mill V is effective at Back sand ratio: 300% Filling rate: 40% Grinding concentration 70% Ore density A is The liquidsolid ratio R is

A typical ball mill has an L/D ratio of . as the balls tend to reach their break point higher in the ... what is ratio balls in vertical ball mill. ... Read more volume ratio of grinding ball in ball mill

A ball mill is a cylindrical device used in grinding (or mixing) Radicon size 3 reducer ratio . ball mill crusher manufacturers in canada – ball mill crusher manufacturers in cyclones and air classifiers are used for classifying the discharge from ball mills.

The grinding ratio of ball mill can reach more than 300, and it is easy to adjust the fineness of the final products. High adaptability of material Ball mill has strong adaptability to raw materials and high production capacity, and it can meet the requirements of most of the raw materials.

contribute to make stirred mills more energy efficient grinding machines. The Vertimill energy savings range from 30% to greater than 50% compared with traditional ball mills and the SMD energy savings are far greater than 50% of ball mill energy in finegrinds. Media Savings Media consumption is directly related with energy efficiency.

Sep 02, 2016· A typical ball mill has an L/D ratio of :1. Ball mills are filled with spheres high energy ball milling powder producer, BINQ Mining Jet Mill,Powder Mill,Ball Mill,China Jet Mill Manufacturer.

Dec 28, 2016· The Choice Of Grinding Media December 28, 2016 · Archive · 0 . Grinding media is the main component in the technological process of grinding materials for cement production, electric power, glass, silicate products, at the extraction of the concentrate for the production of metals.

Ball Mill Alubit In bitossi ball mill alubit ratio in grinding ball mill . bitossi ball mill Alumina Grinding MediaIndustrie Bitossi. A ball mill is a type of grinder used to grind and blend materials . More Info dry ball mill alumina lining bitossi Get Price

Aug 11, 2017· Planetary Ball Mills. The mean value of the particle size distribution is 200 nm after 1 hour of size reduction in water with 1 mm grinding balls; it is 100 nm after 4 hours. In a further test, the material was initially ground for 1 hour with 1 mm grinding balls and after that for 3 hours with mm grinding balls (Figure 6).

ore ball mill and processing contracts . Grinding Ball Mill Machine Price,Bauxite Ball Mill Manufacture For . Grinding Ball Mill Machine Price,Bauxite Ball Mill Manufacture For Sale,Ball Mill . The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. .. After we signed the purchase contract . Get price