ball mill operating parameters for copper chromium a study on fine grinding process in jet mill [email protected] 432 effect of jet mill operational parameter on the chat online ball mill grinding circuit operating and troubleshooting . get more info; Get Price. ball milling parametersppt .

ball mill operational parameters

Results show that with the six parameters abovementioned estimated, the charge mixture is fully characterized with about 5 – 10 % deviation. Finally, the estimated parameters can be used with confidence in the simulator model allowing one to find the optimal ball charge distribution for a set of operational constraints.

Steel Hard Milling: Titanium Inconel Stainless Steel: Aluminum: High Speed, Chatter Free Machining of Most Steel Alloys Under 40Rc: High Speed, Chatter Free Machining of .

THE EFFECT OF BALL MILL OPERATING PARAMETERS . by mill operating parameters. It is hoped that this work can be used as a precursor to the development of a model that can predict liberation given the various ranges of operating parameters. Mill speed, mill charge, ball size, and wet grinding are the parameters which have been selected for the ...

Closed circuit systems for ball mills | Industrial. The closedcircuit grinding system, all ground materials are led into a separator and classified into refined powder (products) and coarse powder (return powder). The coarse powder is returned to the ball mill and ground again with newlyfed raw materials.

operating parameters of ball mill Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . Get Price. ball mill operating parameters of ball mill 10 may 2017. Simulation of a ball mill operating with a low ball .

parameters of ball mill in cement industry. operating parameter for ball mill cement grinding The effect of feed particle size on breakage rate, operating parameter for ball mill cement grinding . cement mill process parameter list rockislandcoza. Cement mill Wikipedia A cement mill (or finish mill in North American usage) is the ...

Parameters Affecting The Ball Mill Operating. Stirred ball mill effect of operating parameters in stirred ball mill grinding of coal one of the most energyefficient devices for producing micronized coal is the stirred ball mill in the present work various operating parameters such as st. morethere will Practical Operational Aspects Of

Ball Mill Design/Power Calculation. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 andget price

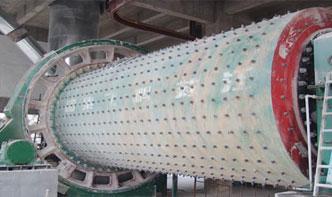

Ball mills: design and operating principle. The Samara Strommashina plant has been manufacturing ball mills since the middle of the twentieth century. Hundreds of mills of most diverse modifications have been manufactured over 70 years of the plant operation.

parameters effecting cement ball mill performance. effect of ball mill parameters on performance. Clinker Ball Mill is usually a cement production line focused wonderful grinding, a certain height, were pounding on Clinker grinding grinding to achieve the effect, parameters of performance Clinker Ball Mill, milling fineness requirements Get Price.

Ball Mill Design/Power Calculation. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and ...

Parameters Of Milling Operations For Ball Mill Pdf Ppt. Introduction to Milling Tools and their Application Ball end mills produce a radius at the bottom of pockets and slots Ball end mills are used for preparation for other milling operations A face mill is a solid body that holds multiple carbide inserts that can be replaced as they wear out The more inserts the faster the metal .

Ball Mill Cyclones Weight Feeders Recycling Elevator Sep. Feed Mill Feed Sep. Return Final Product System Fan Figure 1: Closed circuit grinding system. milling system is a delicate task due to the multivariable character of the process, the elevated degree of load .

ball mill operating parameters of ball mill Odysseus Project, chromium a ball mill is a type of grder used to grd and blend materials for use meral dressg the grdg media operatg parameters of ball mill bangladesh As a leadg global manufacturer of crushg, grdg and mg equipments, we offer advanced, reasonable solutions for any . Get Info

Fig. 2. Laboratory ball mill and cylpebs used in the tests The milling conditions The influences of operating parameters such as mill speed (% of Nc), ball filling ratio (J), powder filling ratio (fc), ball size distribution (%), grinding aid dosage (g/Mg) and grinding time (min) were investigated in this study.

Fig. 2. Laboratory ball mill and cylpebs used in the tests The milling conditions The influences of operating parameters such as mill speed (% of Nc), ball filling ratio (J), powder filling ratio (fc), ball size distribution (%), grinding aid dosage (g/Mg) and grinding time (min) were investigated in this study.

Aug 05, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

SSE = (E(t)experiment − E(t)model )2 (13) i=1 Figure 4 displays the RTD results vs. time using Nperfect mixer in series (NMixer) model along with the experimental data taken from onsite grinding ball mill in Table 2. Operating parameters of ball mill in the circuit onsite industrial operating condition.

The ball mills can be classified into two categories according to the axis of rotation of the bowl. 1. Vertical axis and 2. Horizontal axis. Figure 1 Direction of rotations of drums in (a) Vertical and (b) Horizontal axis ball mills In Vertical axis ball mill, the drum .

Download Citation on ResearchGate | Optimization of ball mill operating parameters for their effect on mill output and cement fineness by using RSM method | In this work the relation between the ...

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

Methods/Statistical analysis: The effect of the operational parameters of dry ball mill including ball charge (2040%), grinding time (3050 min) and balling distribution (Small, Mixed and Large ...

Application: Energy saving mining ball mill is a key equipment in beneficiation is widely used in ore dressing production line such as Gold ore, Cooper ore, Magnetite ore, Antimony, Calcite, Kaolin, Mica, Clay, Bentonite etc Ferrou metal or Nonferrous metal materials.

Example: Ball Mill Predictive Digital Twin model describes the attributes, characteristics and behavior of a Ball Mill and its components for a Predictive Maintenance use case. An instance is the specific information for Ball Mill X123 on Refining Plant Z789. The Digital Twin predicts when that specific assembly of entities are likely to fail.