Peng explains that the specific ball design will balance the ball size, hardness and toughness according to the milling targets in the operational plan. Sino Grinding considers all the targets and environmental factors to supply a ball with a <1% breakage guarantee.

ball milling design

Ball Milling Theory and Practice for the Amateur Pyrotechnician. Printerfriendly version. SKU: 27. By Lloyd Sponenburgh. This is Lloyd's "bible" on ballmilling theory, and a design .

Feb 01, 2018· This video is unavailable. Watch Queue Queue. Watch Queue Queue Queue

Design of Parts for Milling: What follows is a list of recommended design practices for milled parts. The list is not exhaustive, but is what our staff has found to be most useful. Design milled areas so that the end mill required is limited to 3:1 in length to diameter ratio. As shown in the figure below, longer end mills are prone to chatter.

The Challenge: Design a low cost circuit board milling machine optimized to be massproduced. Technical Approach: Several observations on the process of circuit board milling serve as the premise of the design: X and Y resolution of " is sufficient. X and Y positional accuracy and repeatability is important for creating thinly spaced traces.

suspensions (NS) for enhanced delivery wet ball milling by design of experiments (DOE). In this study, via SEOA NS batches were prepared by wet ball milling method. Mean particle sizes and polydispersity indices were determined using a nanosizer. The percent .

Jan 12, 2018· Please subscribe! Thank you for watching! I designed this ball mill entirely for ease of maintenance. It uses Polyurethane Skate wheels and 608ZZ bearings. It has a laptop power supply and a basic ...

Planetary Mills are ideally suited for fine grinding of hard, mediumhard, soft, brittle, tough and moist materials. The comminution of the material to be ground takes place primarily through the highenergy impact of grinding balls in rotating grinding bowls.

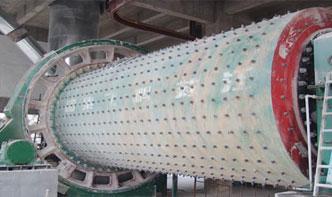

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. These mills are sized from 2 t/h to 30 TPH for wet grinding and from t/h to 30 TPH for dry grinding.

Selection and design of mill liners ... analytical and experimental studies of the solid materials grinding process in the ball mill have shown that it is possible to improve the energy efficiency ...

of the balls is mainly in the direction of the rotation of the mill and not in the direction of the main axis. 2. We consider a perfect layer structure. This means that the balls are lifted up in layers with distance of twice the radius of a ball and with the angular velocity of the mill.

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals, and glass ceramic industry.

is home to a collection of both free and subscriptionbased calculation tools to aid metallurgical process engineers perform comminution calculations. Grinding circuit design tools, including for SAG millball mill circuits, and geometallurgy energy models are available to subscribers.

Optimum choice of the makeup ball sizes for maximum throughput in tumbling ball mills. Author links open ... process was developed using the size–mass balance or population balance approach analogous to the chemical reactor design for firstorder reactions. ... covering a broad range of levels on which a typical ball mill circuit operates ...

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many ...

ball mill foundation design. company is a research and development, production, marketing, service for the integrated enterprise, and it's a professional supplier of mining crushing . »More detailed. Ball Mill Design,Ball Mill Sizing,Design Of Ball Mill. Design of ball mill sizing has strict standards.

Techno Designs is a ball mill manufacturer with an experience in designing, engineering, and manufacturing over 150 grinding mills. We deliver qualityapproved batch type ball mills with sizes in the range of x 2m and 3m x and power ranging from 50 HP to over 1000HP.

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the material that about to be ground, a motor is used to power the system so that the jar can rotate in high speed and using the regulator controls the speed of the rotation of the jar.

A Ball Mill DesignOverview 1 Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Curso

Nov 30, 2015· If the rate of feed increased, coarser product will be obtained and if speed of rotation is increased the fineness for a given capacity is increases. During grinding, the balls themselves wear and are continuously replaced by new ones so that mill contains balls of various ages. Ball mill produces 1 to 50 ton/hr of powder and energy requirement ...

What is Cryogenic Milling? Cryogenic milling, or cryomilling, is the process of using liquid nitrogen to lower the temperate of the material and/or the milling process. AVEKA's cryogenic hammer mills can typically reduce the particle size from small pellets down to the 100s of microns. Cryomilling .