The Manufacture of Portland Cement – New Zealand Institute of .. oxide (Fe2O3) – the raw materials of cement manufacture.. containing significant quantities of SiO2 and Al2O3) mixed with ground brick and water... made during the manufacturing process to ensure the .

cement bricks manufacturing process

It is composed of a thick mixture of water, sand, and cement. The water is used to hydrate the cement and hold the mix together. The water to cement ratio is higher in mortar than in concrete in order to form its bonding element. When mixed, it is a much thicker substance than concrete, making it ideal as a glue for building materials like brick.

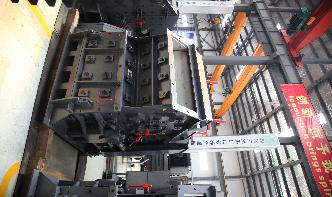

Block, brick paving making machines for a number of industries : Pan Mixers South Africa or PMSA is Africa's leading manufacturer of concrete block, brick and paving making and brick making machines are used in the production of a variety of concrete blocks and bricks, primarily within the construction industry.

May 30, 2014· Types of bricks 11. Concrete Bricks These bricks have either pale green or gray color. These are prepared from a small, dry aggregate concrete which is formed in steel molds by using vibration and compaction. The entire manufacturing process is .

HOLLOW AND CEMENT CONCRETE BRICKS 1. INTRODUCTION: Cement concrete dense/ hollow bricks and blocks are very popular and are extensively use d in building construction throughout the country because of the many advantages such as durability, strength and structural stability, fire resistance, insulation and sound absorption it ... MANUFACTURING ...

Manufacturing Process Know How . The process of manufacturing is simple and standardized. Cement concrete is a mixture of cement, sand and stone chips in correct proportions. The items are mixed in water and churned thoroughly in a concrete mixture. The process involves proportioning, Mixing, Compacting, Curing Drying.

Manufacturing of clay bricks includes following process: Preparation of Clay: Preparation of clay is done manually or by mechanically operated machines (excavators). Preparation of clay consists of following methods:>Unsoiling: Unsoiling is the process of removal of top layer soil which consists of vegetation, Kankar or other impurities.

Global Concrete Block and Brick Manufacturing Market to expand at a moderate % CAGR during . At this pace, the Concrete Block and Brick Manufacturing Market evaluated at 1, billion units in 2016 will become billion units by 2027 end.

The clay brick face industry has utilized bottom ash as a body additive for many decades in the US. Bottom ash has properties that provide many favorable benefits to the clay brick maker. Brick making clays that are plastic in nature form a dense mass when subjected to the extreme pressures of the extrusion process used in the brick ...

Apr 21, 2014· Manufacturing of bricks 1. BY SARTHAK KAURA 2. Preparation of brick earth Moulding of bricks Drying of bricks Burning of bricks 3. Removal of loose soil The top layer of the loose soil about 30 cm depth contains a lot of impurities like organic matter and hence it .

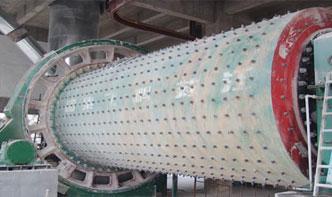

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the ' Clinker ' pages.

What follows is a very brief summary of the most common process of making a concrete structure. Much more information is available from other sources. Designing the concrete mix The first and most important step in the process is to determine the ingredients that will make up the concrete .

cement for manufacturing of interlocking bricks with a good compressive strength of N/mm. 2. The concept of interlocking bricks of size 30x20x18cm was adopted which resulted in a cost effective construction (Bharath, 2012). As per the research work carried out by (Olufemi . .

Fly Ash brick is a product of basic cement clinker materials FLY ASH, STONE DUST/SAND, LIME, GYPSUM and BONDING AGENT. The mix is so ideally worked out to produce bricks of higher strength with consistency as well as uniformity. The manufacturing process is fully automatic with state of art technology. Though a new age product introduced ...

Jan 18, 2018· NEW YORK, Jan. 18, 2018 /PRNewswire/ Global Concrete Block and Brick Manufacturing Market: Overview Concrete block or concrete masonry .

Find here Cement Brick Making Machine, Cement Brick Machine manufacturers, suppliers exporters in India. Get contact details address of companies manufacturing and supplying Cement Brick Making Machine, Cement Brick Machine across India.

Aug 27, 2015· Cement Manufacturing Process August 27, 2015 S. C. Rangwala Cement, Construction Material 0 The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain uniform quality of cement and a high rate of production.

Bricks whose solid ingredient is fly ash have been manufactured. The manufacturing process uses techniques and equipment similar to those used in clay brick factories. The bricks produced were about 28% lighter than clay bricks. The bricks manufactured from fly ash possessed compressive strength higher than 40 MPa.

Fly ash bricks manufacturing has become a big money making business in India. Now people of India have slowly adapting the green brick technology (Fly ash Bricks) which is going to be a savior of our mother nature for years to come.

Portland cement can be made by following two different processes – a dry one and a wet one. Joseph Aspdin first made portland cement in his kitchen stove in England in the 19th century. Lime and silica make up approximately 85% of portland cement. The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore.

8 Main Cement Ingredients Their Functions Cement, as a binding material, is a very important building material. Almost every construction work requires cement.

Concrete brick making machine for sale can produce various of bricks: concrete bricks, hollow bricks, solid bricks, interlocking bricks, lawn bricks and so on. These finished bricks can be used for the road construction, building construction, park construction, water conservancy project, etc.