Home > cement manufacturing process wikipedia india > We have the best service There are various types of mining equipment with green building materials, you can contact us online.

cement manufacturing process in india

Indian Cement Industry is the second largest cement producer in the world after China with a total capacity of Million Tonnes (MT). The Indian cement industry is dominated by 20 companies, which account for almost 70% of the total cement production in India.

MANUFACTURING PROCESS The process of manufacture of cement concrete hollow blocks involves the following 5 stages; (1) Proportioning (2) Mixing (3) Compacting (4) Curing (5) Drying (1) Proportioning: The determination of suitable amounts of raw materials needed to produce

cement manufacturing process ppt india process industry in india trade perspectives. cement production in india has of cement in india. the consumption of coal in a typically dry process system ranges from 20 25% of clinker this.

cement manufacturing process in india, cement manufacturing process... cement manufacturing process ppt india process industry in india trade perspectives. cement production in india has of cement in india. the consumption of coal in a typically dry process system ranges from 20 25% of clinker this.

Cement Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue News provided by Bharat Book Bureau

Apply to 46804 Production Process Cement Plant Jobs on, India's Job Portal. Explore Production Process Cement Plant Openings in your desired locations Now!

Clinkerisation is the heart of cement manufacturing process, where the raw material is fed to preheater at controlled rate through electronic weigh feeder. The feed enters the kiln through cyclones and fuel is fired at the kiln outlet end.

Pyro Processing and Clinkerization. The fuel is ignited and burned out in the combustion zone. The sintering process and the formation of clinker occur inside the kiln. Hot clinker is cooled in the cooler. Ambient air is used to cool the clinker and partially used for coal combustion. The cooled clinker is stored in the clinker yard/clinker silo for cement grinding.

Find here online price details of companies selling High Alumina Refractory Cement. Get info of suppliers, manufacturers, exporters, traders of High Alumina Refractory Cement for buying in India. IndiaMART would like to help you find the best suppliers for your requirement.

Profile Of CCI. Cement Corporation of India Limited (CCI) was incorporated as a Company wholly owned by Government of India on 18th January 1965 with the principal objective of achieving self sufficiency in cement production. The authorised and paidup capital of the company is Rs. 900 crores and Rs. crores respectively.

Ambuja Cement aspires to be the most competitive and sustainable company in the cement manufacturing industry. Acting in a sustainable manner is not only a business imperative but also provides the company with a competitive advantage.

1961 Started blended cement manufacturing in India. Blast furnace slag used as Blast furnace slag used as clinker substitute from TISCO in Chaibasa Unit to manufacture Portland Slag Cement.

Cement manufacturing process ppt india. India India, where coal is the dominant fuel used for cement production, has suffered from inconsistent coal supplies for the past several years Both quality and availability have been hit, while price increases have been noted Cement and power plants have been forced to halt operations at times due to a

These were later on replaced by rotary kilns as standard equipment worldwide. Annual global cement production has reached some /yr and is expected to increase still further to around 4Bnt/yr. Major growth is forecast in countries like China and India as well as .

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

Ordinary Portland cement is the cementing material used in cement concrete hollow blocks. Cement is the highest priced material per unit weight of the concrete. Hence, the fine and coarse aggregates are combined in such proportions that the resulting concrete is workable and has minimum cement content for the desired quality.

High Alumina Refractory Cement (HARB) is manufactured from Calcined Alumina and high purity lime. It is used as a binder for all types of castable refractories. OAL offers two ranges; HARB 70 and HARB 50 with minimum alumina content of 70% and 50% respectively.

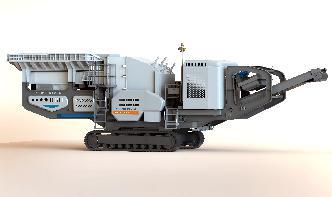

Cement Manufacturing Process Machine configuration. The main component of barite is barium sulfate, which is an important industrial raw material that can be used in chemical, paper, textile, and filler industries. Cement Manufacturing Process Machine is a grinding equipment that is in high demand in the field of barite milling.

"India Cements is one of the leading cement manufacturing companies in India and also a market leader in South India. The Company's vision is to create value on a sustained basis for all stakeholders through lofty standards of transparency, accountability and leadership in cement manufacture.

The production of cement clinker from limestone and chalk by heating limestone to temperatures above 950°C is the main energy consuming process. Portland cement, the most widely used cement type, contains 95% cement clinker.

Cement manufacturing raw materials. If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making. The most common raw rock types used in cement production are: Limestone (supplies the bulk of the lime) Clay,...

India Cements Limited has 7 integrated cement plants in Tamil Nadu and a leading cement manufacturing company in India, cement brands owned by India Cements are Sankar, Coramandel and Raasi Gold. Burnpur Cement. Burnpur Cement from West Bengal is one of the largest producers of cement in Eastern India.