Chemical Composition of Portland Cements. The raw materials used in the manufacture of Portland cement consist mainly of lime, silica, alumina and iron oxide. The oxides account for over 90% of the cement. The oxide composition of (ordinary) Portland cement may be expressed as follows:

cement production process

Other articles where Wet process is discussed: cement: Manufacture of cement: .manufacture are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry powder, or ground dry and then moistened to form nodules that are fed to.

Manufacturing Portland Cement. The basic ingredients of both the dry and wet processes are the same. By mass, lime and silica make up approximately 85% of portland cement. The materials that are commonly used are limestone, shells, chalk, shale, clay, slate, silica sand, and iron ore. Since limestone is the main component,...

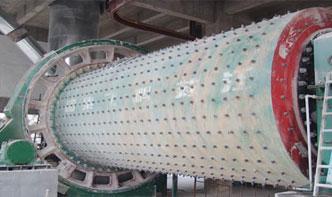

Process Technology of Cement Production. Module 1 (Grinding technology and raw material preparation) will enable participants to obtain a better understanding of the comminution processes and the equipment used for material grinding to ensure high levels of availability, optimise production rates and reduce energy consumption.

Cement production process Date: Views: Those who know a little about the cement production process, mentioning the production of cement, will say "two mills and one burn", they are: raw material preparation, clinker calcination, cement grinding. For some of these process requirements, this website is collected and organized for your ...

Cement Kiln Optimization Controlling a cement rotary kiln is a very difficult task. The process is intrinsically unstable and there are long time delays and large perturbations acting on it. Only a perfect mix of experience, deep knowledge, mathematical techniques and stateoftheart software can achieve optimal behaviour over long periods of time.

Virtual Cement Plant Tour | Portland Cement Association (PCA)

For details about Basic Process of Cement Manufacturing, refer toCement Manufacturing Process

Carbon dioxide (CO2) is a by product of a chemical conversion process used in the production of clinker, a component of cement, in which limestone (CaCO3) is converted to lime (CaO). CO2 is also emitted during cement production by fossil fuel combustion and is accounted for elsewhere.

Composition of cement. The process is known as hydration . This is a complex process that is best understood by first understanding the chemical composition of cement. Manufacture of cement Portland cement is manufactured by crushing, milling and proportioning the following materials:

Kiln and Kiln Shells: As a Cement kiln manufacturers we manufacture all type of process equipments including Vertical and roller Kiln and Shells Kiln Shells is involved in the process of burning the raw mixture thereby resulting in the clinker. This clinker is then subjected to grinding to produce cement.

the cement manufacturing process produces millions of tons of the waste product cement kiln dust each year contributing to respiratory and pollution health risks [1]. The cement industry has made significant progress in reducing CO2 emissions through improvements in process and efficiency, but further improvements are

Oct 07, 2019· The MIT team's process produces the same Portland cement that is already commonly used around the world.

The Process for Making Portland Cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron oxide are crushed and screened and placed in a rotating cement kiln. Ingredients used in this process are typically materials such as .

A cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete.

The study evaluates the energy consumption of both wet and dry processes cement manufacturing plant in Nigeria. En ergy consumption data collected for the period 2003 to 2011 were used to estimate the energy consumption of the crushing, milling, agitation, burning, grinding and bagging operations.

The larger existing kiln in a wet process plant produces 3600 tonnes of clinker per day. The manufacture of cement by wet process is energy intensive and thus uneconomical as compared to dry process and semi dry process.

The C 3 A in portland cement clinker, which typically contains about 13% oxide substitution, is primarily cubic, with smaller amounts of orthorhombic C 3 A. The C 3 A and C 4 AF minerals form by simultaneous precipitation as the liquid phase formed during the clinkering process cools, and thus they are closely intermixed. This makes it difficult to ascertain the exact compositions of the two phases.

The cement industry is wonderful with the latest techniques, and using the dry methods and helping automatic systems, has witnessed tremendous advances in the 160 year history of manufacturing its own. Some of the cement production process like Alumina Cement, entirely is different from Production method of Portland cement.

The cement clinker manufacturing process is a complex process which involves energy conversion and consumption. The objective of this study is to establish the thermal efficiency analytic model of ...

Cement production involves the heating, calc ining and sintering of blended and ground raw materials, typically limestone (CaCO 3 ) and other materials containing calcium, silicon oxides, aluminium and iron oxides to form clinker.

In cement production process, most of raw materials should be crushed, for example, limestone, clay, iron ore, coal, etc. Limestone is the largest amount of raw materials for cement production. After being mined, usually it is of large size and high hardness, so the crush is the relatively more important work for it in cement production plant.

The Manufacturing Process Crude petroleum is separated into its various fractions through a distillation process at the oil refinery. After separation, these fractions are further refined into other products which include asphalt, paraffin, gasoline, naphtha, lubricating oil, kerosene, and diesel oil.

The raw mix burns at 1500 C producing clinker which, when it leaves the kiln, is rapidly cooled with air fans. So, the raw mix is burnt to produce clinker : the basic material needed to make cement. Back Next THE CEMENT MANUFACTURING PROCESS Grinding, storage, packing, dispatch Gypsum and the secondary additives are added to the clinker ...

Cement Equipment Manufacturer. Haijian is a leading manufacturer of cement machinery in China. Since its foundation in 1970, the company has always been committed to manufacturing complete equipment of cement manufacturing plant, a large variety of host products, including cement rotary kiln, roller press, cement tube mill, vertical cement raw mill and rotary dryer, as well as much heavy ...