A major and primary Lead mineral is galena (chemical formula = PbS) which comprises of % of Lead [1]. In order to smelt this mineral, a blast furnace is needed to be used. A blast furnace is an enormous oven which is used to accomplish the smelting processes [2].

cobalt extraction smelting with coke

deals with the succeeding stages of extraction and refining carried out in the smelting works and refineries of Johnson Matthey Co Limited in order to bring the concentrates received from mining company into marketable forms. Operations conducted at the mine result in .

Extraction of Cobalt from Nickel Laterite and Sulfide Ores Cobalt Extraction from Nickel Laterite Ore. Refining of Cobalt. ... The topics discussed include smelting laterite concentrates to sulfide matte, extracting nickel and cobalt from sulfide ores, the slow cooling and solidification of converter matte, extracting cobalt ...

OUTOTEC SMELTING SOLUTIONS FOR THE PGM INDUSTRY L. Aspola Outotec R. Matusewicz Outotec K. Haavanlammi Outotec ... cobalt, and the PGMs and an ever increasing focus on the ... Outotec also has hydrometallurgical processes available for further treatment and extraction of PGMs, which are also briefly discussed. Introduction The platinum group ...

Optimum coke amount was found to be 10% of the slag weight in an opentop furnace for a 1 hour reduction time in the temperature between 1703 K and 1753 K. Similar conditions in a closedtop furnace resulted in higher cobalt and copper contents of the metallic matte, recoveries and reduction rates, as compared with the opentop furnace.

Start studying CHAPTER 11 IRON AND STEEL PRODUCTION. Learn vocabulary, terms, and more with flashcards, games, and other study tools. Search. ... The extraction of iron from its ore (hematite, magnetite) is performed in the ??? ... causing smelting reactions that extract the metal from its ore.

Jul 30, 2014· Cobalt is a chemical element with symbol Co and atomic number 27. Like nickel, cobalt in the Earth's crust is found only in chemically combined form, save for small deposits found in alloys of ...

Cobalt processing, preparation of the metal for use in various products. Below 417 °C (783 °F), cobalt (Co) has a stable hexagonal closepacked crystal structure. At higher temperatures up to the melting point of 1,495 °C (2,723 °F), the stable form is facecentred cubic. The metal has 12

Tavener Process Smelting Gold with Lead Flux. ... enter the furnace with the manganese ores and to a smaller extent with the coke and the carbonate fluxes. In the smelting zone some ofit will be reduced to metal. Get Price; process of manganese smelting . ... Cobalt extraction Wikipedia ...

Aug 20, 2008· In the modified Caron process using the solvent extraction nickel/cobalt separation step, this has the effect of increasing the requirement for the use of hydrogen peroxide, which is added to the nickel and cobalt containing solvent extraction stage feed liquor, to convert the majority of the cobalt to the trivalent state. ... Coal or coke as a ...

In chemistry, a reactivity series (or activity series) is an empirical, calculated, and structurally analytical progression of a series of metals, arranged by their "reactivity" from highest to lowest. It is used to summarize information about the reactions of metals with acids and water, double displacement reactions and the extraction of metals from their ores

Une partie de l'électrolyte usé entre dans le circuit de récupération du cobalt et est purifié par l'enlèvement du fer, du cuivre, du nickel, et du zinc avant la précipitation du cobalt en hydroxyde de cobalt. Ceci est accompli par l'addition de plus de chaux pour élever le pH jusqu'à ce .

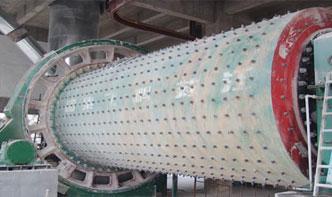

cobalt ore smelting furnance. cobalt extraction smelting with coke Quartz Crusher Coke is used as a fuel and as a reducing agent in smelting iron ore in a blast ... get more information cobalt ball crusher Josephine Nwakaego Foundation. Manufacturing, Supplies and Services to Copper / Cobalt ...

The specified sulfidization can be used in a mixture with other known sulfidization, such as pyrite or gypsum, reduces emissions of sulfur dioxide into the atmosphere, increasing the extraction of Nickel in matte and reducing lumpy consumption of metallurgical coke. 3 fcrystals, 1 table.

Coke is a pure form of coal that contains carbon and is essential in the extraction of metals from their oxides. There is another process in which the galena mineral can be smelted through. It also requires two chemical reactions to occur within the furnace. 1) Due to the sulfur content, carbon from the coke will not be able to reduce lead.

Nov 21, 2018· MGX Minerals Announces Completion of Gasification Scoping Study for Petroleum Coke to Hydrogen with Vanadium, Nickel and Cobalt Extraction

In all, % of nickel was extracted from the leach liquor tripping of cobalt and nickel from the organic phase Table 3 shows that HCl is sufficient for the stripping of cobalt and nickel as % of Cobalt and nickel extraction cobalt and % of nickel were stripped from It is very clear from Fig. 5 that cobalt was the organic ...

Considering the similar studies from literature and highest nickel and cobalt extraction into account, the process parameters optimized as; leaching at 104°C with 378 g/L nitric acid concentration, 48 hours of experiment duration, 600 µm particle size using S/L ratio of 1/5 wt/vol. % nickel and % cobalt

Recovery of copper and cobalt from smelter slag using reductivesulfurizing smelting method was performed in this study. The effects of reductive agent (coke), sulfurizing agent (pyrite), slag modifier (CaO) and smelting temperature and duration on the extractive efficiencies of Cu, Co .