The technology should be suitable for retrofits,, the conversion of a copper heap leach, solvent extraction (SX) and electrowinning (EW) facility once the oxide and transition material is exhausted (Valkama, 2013). Throughout this paper, 'copper sulphides' describes both .

copper heap leaching papers

methods such as dump and heap leaching. The most successful heap leaching operations have been those processing copper oxides and secondary copper sulfide minerals such as chalcocite. Together with dump leaching of mine waste, heap leaching contributes about 20% of annual world copper production (Watling, 2006). The leaching of several lowgrade

This paper describes the design process and outcomes of a raffinate heating system, using submerged combustion technology, at a copper heap leach mining facility in Chile. The purpose of heating the raffinate was to improve the leaching performance during the cooler evenings and winter months.

Jul 06, 2004· Acid heap leaching is widely applied around the world for the purpose of recovering copper from copper oxide ores. Nevertheless, environmental issues associated with the large volumes of spent ore left by leaching have received only limited attention from the mining and research communities. At sites with a positive water balance, seepage contaminated with residual metals resulting from ...

Despite the importance of heap leaching for copper, gold and silver production worldwide, there are no clear standards or guidelines for developing heap leach metal production forecasts. There is considerable variation among copper and gold producers that apply heap leaching technology as to how such modeling and forecasting is applied at the ...

More ↓. Heap Leaching. Heap leaching is a method used most commonly for the mining of gold. Along with heap leaching comes many environmental concerns and considerations. In order to decrease these environmental concerns, there must be regulations placed on the mining of gold.

Referred Conference Papers Chengqian (Charles) Wu, Ahmad Ghahreman, " Parameter Study of the Activated CarbonCatalyzed Arsenic Oxidation Process Under Dynamic and Continuous Conditions" 58 th Annual Conference of Metallurgists (COM) Hosting Copper 2019, Vancouver, Canada, August 18 .

reduced its leaching activity. 1. Introduction . Compared with the traditional metallurgical method, copper biohydrometallurgy is a new way, which is more suitable for leaching lowgrade and difficulttotreat copper ore, and has advantage of mild reaction, simple process, low energy consumption and environmental protection [1].

The leached liquid containing the dissolved copper, known as a pregnant leach solution (PLS), is later collected and further processed to extract the copper. The liquid leachate may lead to TENORM contamination in the surrounding environment by seeping into the ground water at abandoned and active copper mining sites.

Aug 19, 2018· The data showed that the copper leaching kinetics of the aerated heap was greater than that of the unaerated heap within a certain leaching period, after which there was no effect of aeration on the copper leaching kinetics.

Heap leaching belongs to the group of percolation leaching processes and operates over ground. The procedure is illustrated in Figure oxide copper ore is piled up on leach pads, which have a slight slope of approx. 3° and a rubber lining, which seals the ground under the heap.

Isotherms Deng 2019 the sulphide precipitation of behaviour of Cu and Au from their aqueous Oraby 2019 Gold extraction from paleochannel ores using an aerated alkaline glycine lixiviant for consideration in heap and insitu leaching applications Tauetsile 2019 Activated carbon adsorption of gold from cyanidestarved glycine solutions containing copper. Part 2.

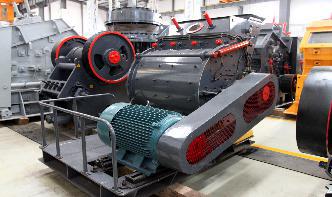

Sep 02, 2016· BINQ Mining . used copper leaching plant price,copper beneficiation is a preferred method of leaching copper ore Heap Leaching, .xyz Heap Leaching Heap Leaching is being done these days on ...

The ultimate MicroSprinkler for full coverage. for heap leaching in Copper, Uranium and Gold Mines. GYROTurbo Mining Sprinklers The ultimate MicroSprinkler for full coverage.

While heap leaching for copper was under discussion in the 1920s, he said, leaching of residual material in old stopes began in 1923 at Bisbee, Arizona, USA. This was followed by the insitu leaching of ore left over from block caving at several mines, including Ray and Miami; in the late 1950s, Miami created a blockcave stope specifically for lowgrade ore leaching.

Highlights Crushed ore agglomeration as a pretreatment step for heap leaching is reviewed. The acceptance of binder is limited due to the lack of acidtolerant binders. Concise overviews of quality control and characterization tools are provided. Different agglomerationheap leaching systems are summarized. HPGR grindingagglomeration may have some advantages.

This process uses aqueous (waterbased) solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps: heap leaching, solvent extraction, and electrowinning. Heap Leaching is the process of using percolating chemical solutions to leach out metals. Heap leaching is very commonly used for lowgrade ...

Jul 06, 2004· Acid heap leaching is widely applied around the world for the purpose of recovering copper from copper oxide ores. Nevertheless, environmental issues associated with the large volumes of spent ore left by leaching have received only limited attention from the mining and research communities.

The evolution of cyanide heap leach closure methods Parshley et al. 74 | Mine Closure 2012, Brisbane, Australia When the first modern heap leach closure regulations were promulgated in the State of Nevada, USA, in 1989, the requirements for closure of heap leach facilities were based on limited information and a number

Sulphuric acid heap leaching of nickel. The method is an acid heap leaching method like that of the copper method in that it utilises sulphuric acid instead of cyanide solution to dissolve the target minerals from crushed ore. The method has been developed by European Nickel PLC for the rock laterite deposits of Turkey and the Balkans. See also

Stability Analysis and Stabilization of Miduk Heap Leaching Structure, Iran 3 Figure 2. Isolated layers of Sarcheshmeh copper heap leaching structure 2 contact line of the two planes has a longitudinal slope, so the sliding block generally moves in a wedge form. 8. Ore .

Oxide copper leaching and modeling We can customize heapleaching designs, modeling of heaps, and process improvements to optimize copper recovery. Smelters Today's smelting technologies must match the operational culture and optimize sustainability. We offer furnace technology that exceeds industry norms and operational expertise.