Ore Concentration by Froth Flotation ... The copper ore slurry from the grinding mills is mixed with milk of lime (simply water and ... The waste material that comes out of the bottom of the tanks at the tail end of this process is called "tailings. Read More

copper ore concentration processing

Tumbling mills with steel rods or balls, sized ores as the grinding media are used in the last stages of comminution. Grinding is usually performed "wet" to provide a slurry feed to the concentration process. Dry grinding has limited applications. There is an overlapping .

See Article History. Zinc processing, the extraction of zinc from its ores and the preparation of zinc metal or chemical compounds for use in various products. Zinc (Zn) is a metallic element of hexagonal closepacked (hcp) crystal structure and a density of grams per cubic centimetre.

Ore Beneficiation Process. As one of the leaders of mineral processing industry in the world, Xinhai firstly gained ClassA design qualification, and possessed mine design institute and beneficiation research institute to provide technical support for mineral processing service, aiming at customizing professional mineral processing...

Copper ore divides into ore sulfide,ore oxide and mixing ore according to its oxide rate . The main process for copper ore is flotation, for refractory mixed copper ore and refractory oxide ore, normally use hydrometallurgy process .It is a high technological enterprise that integrated research, manufacture, sales and service .

recovery rate of copper oxide minerals ranged from 67 to 100 %. Furthermore, with increasing the amount of liquid phase, copper recovery increases as well, and copper oxide minerals were completely leached out. Besides copper ions, considerably high ferrous/ferric ion concentrations were achieved in the leach solution. This concentration was

Copper ore enrichment is a mechanical process of recovering ore before it undergoes smeting. The copper ore enrichment technology used by the KGHM Concentration Plant makes it possible to successfully recover copper and silver as well as other elements from the extracted ore.

Miningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, mineral extraction process and the concentration of ore.

This video deals with metallurgy process . Concentration of ores

iron ore concentration conveyor; silver ore gravity concentration; iron ore concentration floatation process; gold ore crushing and concentration; bayer s process of bauxite concentration; nickel ore concentration plant; concentration of bauxite ore; manganese ore concentration plant; copper ore concentration processing; particle size ...

Extraction of Copper. Chalcopyrite(CuFeS2) is the commonest copper ore. Copper is mainly extracted from the sulphide ore(Cu2 S) by the self reduction process. The ores are often low grade (% Cu) and require concentration (up to 1520% Cu). The process contains the following steps.

Customers want, and that is our goal, we produce ore crusher( what is copper concentration process), mill, crusher, mobile crushing plant, processing equipment, according to the specific needs of our design and production lines, fully the interests of customers.

Ore processcrushing plant and mill for mineral ores beneficiation . Those ore processing plant is most like jaw crusher, ball mill, . We are copper ore process and concentration plant supplier for .

Lead/Zinc Ore. Lead and zinc often occur in the same ore. Copper is also present in some ores. Froth flotation is again employed to produce marketable concentrates of both. The process is identical in principle to the flotation of other minerals. The figure on the right is a .

Leaching: The powdered ore is dissolved in a chemical, usually a strong solution of NaOH. The chemical solution dissolves the metal in the ore and it can be extracted and separated from the gangue by extracting the chemical solution. Extraction of the Aluminium metal .

COMMINUTION AND SEPARATION30. The first step in separating copper from other minerals in ore mined by underground or open pit methods is comminution (pulverization) of the ore chunks—essentially from boulders to grains of sand. (Mining is actually the first stage of .

This kind of ore is usually processed by mill running and then smelting, and the copper recovery is about 35% during the mill running process. Sun at al. [14] performed the copper leaching from low grade copper oxide ore by sulphuric acid, and they have obtained leaching percent of cop per over 90%.

The different steps in extraction of copper are: Crushing and Concentration: The ore obtained from mines are broken down into small piece by jaw crusher and then pulverized. The ore being sulphide ore is concentrated by froth floatation process. Pulverized ore is kept in water containing pine oil and the mixture is agitated by passing compressed air.

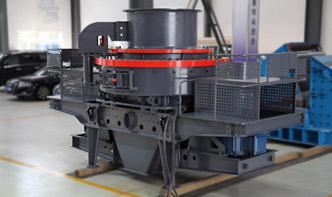

Ore Concentration process: Usually, flotation process is adopted for copper or beneficiation. Common equipment used for Copper Oxide ore Concentration Process Equipment commonly used for copper ore processing includes: Jaw crusher, fine crusher, ball mill, electronic feeder, spiral classifier, mixing tank, flotation machine.

At present, the global average copper ore grades for copper mines is approximately % of Cu content and this number is expected to decrease as mines with higher ore grades become exhausted [17,18,19].

Copper ore processing: The copper ore beneficiation production line generally adopts a relatively simple a period of grinding, the fineness 200 mesh accounts for about 50% to 70%,1 rough selection, 2~3 selections, 1~2 the particle size of the copper mineral is relatively fine, a stage grinding process may be of the concentrating plants that deal with the porphyry ore .

In this process copper ore is mined, crushed, ground, concentrated, smelted and refined. The mining, crushing and grinding portions of the processing are extremely energy intensive since the rock must be reduced essentially to talcum powder fineness in order to separate the copperbearing minerals from it.