The resulting concentrated solution, after some purification, is suitable for the recovery of cobalt by electrowinning. From ores. For coppercobalt ores, a sulfide concentrate is roasted under controlled conditions to transform most of the cobalt sulfide to a soluble sulfate while minimizing the change of copper and iron to their watersoluble ...

copper recovery from copper sulphate solution machinery

Start studying Copper Lab. Learn vocabulary, terms, and more with flashcards, games, and other study tools. ... What will be your source of copper? copper nitrate copper sulfate dissolved pennies copper chloride pure copper metal. ... What is the green or blue color in the solution due to? chlorine chloride copper(II) cations solid copper metal ...

The recovery of copper from a pregnant sulphuric acid bioleach solution detrimental to the downstream recovery of copper, nickel, and cobalt with chelating ion exchange. The solution therefore has to be purified of iron prior to using ion exchange for metals recovery from the solution. A popular way of purifying aqueous solutions from iron

The zinc recovery reaches in both SART process options. Instead copper recovery overcomes 90% in onestage option for every Cu/Zn molar ratios simulated. However, copper recovery falls up to 65% in the twostage option for a Cu/Zn molar ratio of

May 05, 2018· Solutions manual for fitzgerald and kingsleys electric machinery 7th edition by umans

CopperAmmonia Complex . When concentrated ammonia solution (ammonium hydroxide) is added to a clear, light blue, aqueous solution of copper(II) chloride, a powdery, light blue precipitate of copper(II) hydroxide forms. Further addition of ammonia causes the copper ion to go back into solution as a deep blue ammonia complex.

The downward migration of the Cu ++ ions and the greater density of the copper sulphate solution keeps the blue copper ions away from the anode. Of course the cell must not be moved or disturbed, and the current through it must be kept flowing to maintain this state, or the copper ions would diffuse througout.

A revised cost evaluation of the cobalt recovery process was obtained to determine the effects of these process modifIcations. The estimated total capital cost for a plant processing 10,000 gpm of spent copper leach solution containing 26 ppm Co was million. With credits for nickel, zinc, and copper

Dec 10, 2013· Ammonia and ammonium salts have been recognized as effective leaching agents in hydrometallurgical processes due to low toxicity and cost, easy recovery and high selective recovery of metals. ... The ammonia leach for copper recovery, leaching and recovery copper from Asmined materias. ... E. Padhan, Palai, Nathsarma, Park ...

In order to help our discussion of the effect of adding ammonium chloride to the copper sulfate solution, the compositions of s copper sulfate solutions with addition of different amounts of NH 4 Cl were calculated using Visual MINTEQ, a chemical equilibrium model frequently used in related fields to calculate metal speciation, solubility ...

their evidence on effective recovery of metals, especially copper, which dissolves easily in ammonia solution. Ammonia leaching was first applied and developed for recovery of copper from its metallic and oxide raw materials. Copper forms well soluble and very stable complexes ([Cu(NH. 3) 4] 2+) and can be leached at ambient conditions due

Impure copper is purified by electrolysis in which the anode is impure copper, the hode is pure copper, and the electrolyte is copper sulphate solution. An alloy is a mixture of two elements, one of which is a metal. Alloys often have more useful properties than . Extracting Copper from Copper Sulphate. Extracting Copper from Copper Sulphate ...

Alternative solution purification in the hydrometallurgical zinc production by adding zinc dust. In the second stage, cobalt and the remaining nickel are precipitated at high temperatures by adding zinc dust, antimony trioxide and copper sulphate if necessary. Figure 3: Reverse solution purification

This project has many variables, including the cleanness and smoothness of the key, the strength of the copper sulfate solution, and the strength of the current. If a black sootlike substance starts forming on the key, your solution is not strong enough for the current. Take the electrodes out and add more copper sulfate.

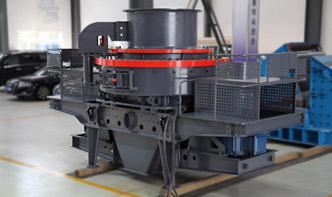

Improve your bottom line and reduce waste by compacting scrap metal in a hydraulic briquetting machine from Applied Recovery Systems (ARS). With our briquetting machines, you can transform industrial turnings, filings, chips, clippings and even metallic dust from copper, brass, aluminum and other metals into compressed briquettesworth more than noncompacted scrap metal.