Hp Mining Mill Backing Material. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon ... HGT gyratory crusher has many incomparable advantages such as high crushing efficiency, low production cost and simple maintenance method, which can satisfy the requirements about high efficiency and coarse crushing. Output ...

crusher backing material

Rubber Scalping Screens. This product is designed for highimpact materials. Made with 60 durometer, wearresistance rubber. Sold with or without skid bars. Unified® offers a full range of openings, including square, rectangular, or, round holes. Special hold patterns are .

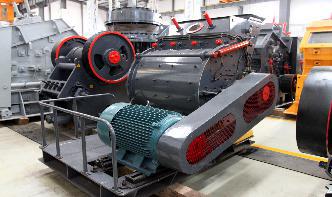

is a manufacturer of aggregates and mining crushing and screening equipment with a continuous devotion to meeting the needs of our customers.

Quilters use extra wide fabrics for beautiful, seamless quilt backing. We sell only the best brands including Timeless Treasures Fabrics, Robert Kaufman Fabrics, Wilmington Prints. All fabrics are cotton, 104 inches, 106 inches, 108 inches or more.

Nov 30, 2015· A new backing compound for gyratory and cone crushers offers improved userfriendliness, sustainability and strength. Replacing two existing products, a new and improved, lowodour crusher backing compound tackles many of the application's big challenges headon. Crushers, used in a number of industries to break materials into smaller chunks,...

Home » Crusher Backing. Shipping Globally. CMS Cepcor® is the authorised UK and export distributors for Korrobond® crusher backing and release agent products, our extensive stock holding in the United Kingdom allows us to despatch even the largest order promptly worldwide.

Crushing and Minerals Processing. In addition, HE Parts offers crusher parts for most brands and makes in the market along with a full range of wear products including wear plate, ceramic liners and mill liners. HE Parts can offer minerals processing, plant asset management or the entire scope of maintenance support required by our customers.

Oct 08, 2019· The material that is chosen to back a rug is important for a number of reasons. Rugs need to breathe in order to help air, gas, and moisture move through the rug. Without the proper type of rug backing, a rug may succumb to mildew, mold, extreme wear, and some types of rug backing .

crusher lining plate backing filled epoxy compound adhesive BD65 cone crusher backing filling repair epoxy compound,crusher ceramic lining plate filling material epoxy backing adhesive Packing details of our BD65 crusher backing wearing resistant filling repair compound epoxy adhesive

Apr 24, 2012· The conveyor should always remove material at least as fast as the feeder meters material to the crusher, as shown in Figure 3; 1½ times feed rate is ideal. This will prevent material from backing up into the crusher at the discharge, which can cause over grinding. Material backup at the discharge can also overload the crusher drive.

Aggregate and Mining – Crusher Backing; Bulk Order Consumer Craft Epoxy Resins; Concrete Coatings and Joint Filler; Construction Epoxies DOT / C881 Products; Epoxy Composite Systems; Industrial and OEM Solutions; Machinery Installation Grouts; Precast Form Coatings and Repair Materials; Wear Resistant and Maintenance Products; Private Label Manufacturing; Resources

Crusherbacking compound to improve machinery life. It is used for filling cavities between the upper part of a crusher and its outer jacket and between the supporting cone and inner jacket in cone crushers, as well as to fill the gaps between the upper part of stand and crusher jaws and the supporting cone and inner jacket in gyratory crushers in the quarrying and mining industries.

loctite nordbak crusher backing materials,1 Loctite Nordbak Backing Material is a solids epoxy compound for backing wear plates in cone crushers and . crusher backing kits classichotel Crusher Backing resin compound for cone crushers is a 2 part polyurethane system used in cone crushers. of Nordback Backing Material required Get Price.

Sep 01, 2016· The backing material of adhesive tape is critical for its functionality. You will learn about why this is the case in the tesa Wikitapia, the adhesive dictionary from tesa. The tape backing turns an adhesive into adhesive tape. In other words: it is the backing that holds the adhesive in place. But it also has critical functional importance.

#GenuineAlternative | Setting the Standard CMS Cepcor® is the leading aftermarket manufacturer and supplier of crusher spare parts, mining grade crusher liners and crusher service to mining, aggregate production and associated crushing industries globally.

Nordbak® Backing Material (heat distortion temperature, ease of mixing and pouring) LOCTITE ® Nordbak Accelerator for Backing Material • Added to resin prior to mixing to speed the cure of the material when equipment and ambient temperatures are below 55°F (13°C) • Can be used with the following products:

Apr 14, 2015· crusher backing. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand.

Crusher Backing Compound Crusher Backing. Pour at one place and allow backing material to fill the cavity and push out the air in front of it. Use dam (tin, cardboard or clay, etc.) to direct the flow when necessary, until full. Unmixed resin (different color clinging to the sides and bottom) should not be drained into the crusher.

The material would have to be nonylphenol and BGE free, and capable of withstanding the high service temperatures (exceeding 200°F) that occur during the crushing process. After a thorough analysis of requirements, we developed a rock crusher epoxy backing material kit, and made it available in 2gallon, 5gallon, and 55gallon sizes.

Material Coverage Conversion Chart All rock products, rip rap, boulders and soils are sold by the ton. All mulches and plant mixes are sold by cubic yard. 1 Ton/Cy of the material listed below at a 3" depth will cover square feet Concrete Sand 86 Sq. Ft. Squeege 83 Sq. Ft. Pea Gravel 83 Sq. Ft. 314" Rock 77 Sq. Ft. 1 112" Rock 77 Sq. Ft.

Crusher backing is a twopack product originally designed to replace white metal, which was traditionally used as a shock absorbing material in cone ... Read More copes cone crusher backing material .

Features Solid epoxies system for backing wear metal in crushers and grinding mills Temperature range: 28°C to +104°C Applications Suitable for filling gaps .

NORDBAK® STANDARD BACKING is a tough, resilient and ideal backing for smaller Cone Crushers, Gyratory Crushers, Rotating Mills, Pulverisers and other heavy reduction machinery. 7459 9998 (10 kg)