Just as other mechanical components, roller bearings can also undergo premature failure or housing defects for various reasons. One must differentiate bearing durability determined by loan fatigue during operating speeds and bearing service life, which determines the bearing uptime, before a bearing is for various reasons decommissioned.

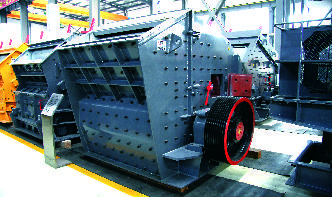

crusher bearing damage

The bearing operates in a hummer crusher, thus the vibration signal acquired on the housing contains a lot of impacts that originate in various sources. In the case of local damage detection it

Jaw crusher bearing monitoring with SPM HD Mining operations include a number of critical applications which may cause severe disruptions in the production process in case of malfunctions. One such piece of equipment is the jaw crusher.

Motor bearing damage detection using stator current monitoring Abstract: This paper addresses the application of motor current spectral analysis for the detection of rollingelement bearing damage in induction machines. Vibration monitoring of mechanical bearing frequencies is currently used to detect the presence of a fault condition.

been replaced, but the cause of damage has not been rectified. Due to the high level of complexity of the interaction between the individual components of a bearing inside the engine (see Fig.), the cause of damage is generally not easy to recognise. This is frequently not to be found in the bearing itself, but in the surroundings of the bearing.

the bearing is sufficient to allow successful operation of the hydrodynamic film under expected loads, static and dynamic, as well as avoiding damage during the requitups and shutdowns. The visual observations of the damaged bearing, discussed in this paper, provide the basis for calculating the loss of .

Pioneer Motor Bearing operates one of the leading fluid film bearing repair services in the and Canada. Our service and repair department is the longest running nonOEM bearing repair service in North America for industrial, power generation and marine customers.

This professional crusher blog contains crusher basics which focuses on the jaw crusher, hammer crusher, impact . crusher, crusher failure, . causes, mainly due to the . Impact Crusher Yuanhua mechanical failure to provide the following four common . of course, also cause excessive bearing .

addition, roller bearings can handle high oil temperature, if there is ever a temporary lubrication failure. Roller bearings for improved loadcarrying capacity, effi ciency and fl exibility The Gyracone is designed for the heavyduty crushing applications expected of a modern cone crusher. It uses the latest in heavyduty roller bearing ...

Failure analysis revealed that the engine failed due to electrical discharge damage on the number 1 bearing. The electrical discharge damage was consistent with an electrical arcing path associated with the starter generator. Such a failure mode was recognized by Transport Canada and is identified in Service Difficulty Report No. AV200705 ...

Bearing Case Study Rushland, PA (USA): November 10, 2008 When the Eureka Stone division of James D. Morrissey needed to upgrade a crusher from diesel to electric drive, the project included new bearings for the jackshaft. Typically, splitblock SAFtype bearings are used in such applications because of shaft size, but it is difficult to set

crusher through features such as main frame inspection ports, cartridge countershaft boxes and speciallydesigned tools. Structural integrity The critical load bearing components of the Raptor cone crushers meet specifications that typically exceed what is commonly offered in a conventional cone crusher. The major components are cast

12 Best Wheel Bearing Greases in 2019. There are many aspects involved in the process of vehicle maintenance, which will be required to keep a car running at its optimum level. Just through normal use, the moving parts of a vehicle can suffer wear and tear. Besides this, the movement of the components generates a significant amount of heat

Insulating Ball Bearings from Electric Arc Damage in Electric Motors. ... Once electric arc bearing damage has begun, excessive vibrations, increased heat, increased noise levels, and the reduced effectiveness of the lubricant will contribute to shorten a bearing's service life.

Publ. No. WL 82102 Rolling Bearing Damage TI No. WL 0011 FAG Videos on Rolling Bearings TI No. WL 809 Aluminium Heating Ring for Cylindrical Roller Bearing Inner Rings TI No. WL 8014 Mounting and Dismounting of Spherical Roller Bearings with Tapered Bore

Acceleration enveloping to detect bearing damage In any manufacturing or processing plant, machine breakdown has significant consequences. Productivity and profitability are usually affected and there is also a health and safety risk. Surprisingly, however, the cause of the breakdown is rarely identified. Instead, the bearings that were

Jul 16, 2012· Fig. 1 The appearance of an overload failure depends on whether the shaft material is brittle or ductile. W hether related to motors, pumps or any other types of industrial machinery, shaft failure analysis is frequently misunderstood, often being perceived as difficult and expensive. For most machine shafts, however, analysis should be ...

The coal mine hammer crusher can adopt two different transmission forms of pulley and reducer according to the power of the equipment. Normally, the pulley drive is only used for hammer crushers up to 250 kW, and hammer crushers larger than 250 kW are driven by reducers. 2 Failure source of hammer crushers (1) Design processing defects.

damage and condition at the time the damage occurred, it is possible to prevent the same kind of damage from reoccurring. Table gives the main causes of bearing damage and remedies for correcting the problem. 16. Bearing Damage and Corrective Measures Bearing Damage .

CRUSHER WITH TWO CONFIGURATIONS. CI512 Secondary Crusher. The Prisec Horizontal Shaft . Impactor (HSI) range of crushers ... pass through the crusher without causing severe damage. A major advantage of this system, ... Crusher bearings are housed in a heavy duty purpose made housing .

relationship of crusher bearings grinding mill equipment. Crusher Bearing Crushers Relationship Of Crusher Bearings ditecteam The Crusher of maintenance Crusher bearing position is most easily broken correctly handle the relationship between the use of maintenance and repair Get Price NEW Timken Conehead Taper Bearing 2415

Jul 05, 2017· The opposite problem, insufficient lubrication, can cause bearing temperatures high enough to produce discoloration and softening of bearing steel. If this occurs, the bearing should be replaced. To prevent this type of damage, fill the bearing housing with .

bearing for jaw crusher,bearing for jaw pulverizer Time: ID:7903 Related news and images with bearing for jaw crusher,bearing for jaw pulverizer. Read more Used bare jaw crusher and portable jaw crushers for mining and crushing aggregates, also called trituradoras de mandibulas o . Get Price >>

The adjustment of vacuum pressure is directly related to the lubrication state of the roller bearing. Too high or too low oil level will cause oil leakage or bearing damage. Because of the importance of roller lubrication system to grinding bearings, the fault of roller bearings can be diagnosed quickly by simple methods in normal production.