compound (open mill mixing) but also warming of premixed compound (known as warming or cracker m ills), or for cooling compound mixed in an internal mixer (known as dump mills). The main mechanical hazard is the nip between the main mill rolls in forward (and reverse) motion.

difference between calcite roller mill and ball mill

In ringroller mills rollers feed solid coarse particles against a stationary grinding ring. The particles are broken apart by the resulting compression forces. Equipment Design In a ringroller mill, the material to be milled is fed into the grinding section . The moving roller forces the coarse material against the stationary grinding ring.

Jul 28, 2011· Difference Between Sheet and Plate. There is a breakdown mill that rolls this ingot back and forth in such a manner that its thickness is brought down to a few inches. Further rolling is required to make plates and sheets of the metal. While plate is mostly used in aviation, machinery, and transportation industry,...

Generally speaking, our HGM series ultra fine powder grinding mill can process the limestone powder in a range between 300 mesh to 2500 mesh, compare with other models of ultra fine mills, the HGM series has a larger capacity, such as, for 800 mesh limestone powder grinding, the maximum capacity of our ultra fine powder grinding mill can up to 30 t/h.

Stainless Steel Sheet Finishes. A bright, coldrolled finish is the most commonly "Mill" finish for light gauge stainless steel sheet. It resembles a very hazy mirror, with some reflection evident. It is obtained by a final light roll pass of the sheet through polished rolls. This is the generalpurpose coldrolled finish that can be used as is,...

Zirconia (YSZ) grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic materials. Zirconia grinding media provides a virtually contaminationfree ball milling solution for a variety of industries.

Loesche roller grinding mills, ensuring their reliability and safety. Each of our drygrinding installations thus represents our technological prowess, offering advantages that ensure the competitiveness of our customers: • No metallic contact between grinding components (even when a coal mill is empty), thus avoiding the generation of sparks.

impact of calcite use Feldspar Crusher Sales machinery. impact of calcite use. impact of calcite use excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (impact of calcite use) in more than one hundred of the worldsales of ...

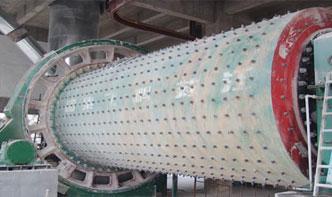

CHAENG+Perumin34 Mining Convention+ball mill, rotary kiln+Sep 1620, 2019 1 Páginas CHAENG+Sand crusher production line+Mine industry+Tight combination, easy operation

As nouns the difference between ball and gala is that ball is a solid or hollow sphere or ball can be a formal dance while gala is (uncountable) pomp, show, or festivity. As a verb ball is to form or wind into a ball. As a interjection ball

mill, etc). 2. Grinding media The grinding media used are, generally, balls and cylpebs. In compartments of coarse and medium grinding are used balls, and in that of fine grinding, balls or cylpebs. In any compartment, sizes of grinding media must be correlated with the size of the material. Between the balls are formed free spaces (emptiness).

Jun 19, 2015· The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball Mill Working Principles of ballonball VS ballonshell grinding. The Motion of the Ball .

Ensuring quality control at America's largest steel mill. As the largest steelmill facility in the country, it is the size of a small town and boasts a production capacity of up to metric tons of steel each year, including mild steels, highstrength and advanced highstrength steels, as well as highcarbon and structural steels.

Ball nosed cutters: slow nose speed. The biggest challenge with ball nosed end mills of various kinds is slow nose speed. As you get closer to the tip, the diameter on the ball gets smaller and smaller, finally going to zero. As a result, the cutter must perform over a wide range of surface speeds and chip loads at different depths in the cut.

This will usually not be necessary with a ball mill due to its higher energy consumption resulting in a sufficiently high temperature in the mill. Grinding of blended cement with wet additives may require supplementary heat from a hot air generator whether the mill is a ball mill or a vertical roller mill.