Sep 10, 2009· Gears and rolls almost HAVE to be in sync. Rolling a wedge, as Bob mentions, will tend to roll a taper edged crescent, curve the stock. That was a problem once upon a time in my rolling mill. Worn window, and the upper roll ahead of the lower also rolled a wedge. 15 tons of sheet shot out the side of the machine. (Where I worked, not MY machine!)

discuss steel rolling mill rolls

Apr 22, 2012· (Roll forming: ) This film takes you through the processes within a hot rolling mill. You'll get to see the different stages all t...

's Rolling Mill Rolls Support the World Steel Industry. In 1961, became the first company in the world to adopt the "centrifugal casting" method for the production of mill rolls. It enables to produce a multi layer composite rolls, which revolutionized mill roll material .

Samples from a couple of work rolls employed in a hot rolling steel strip mill were examined by scanning electron microscopy in order to study their surface, as well as the wear mechanisms ...

A 3 High Rolling Mill consists of three rolls and is typically used for either performing multiple reduction passes by wrapping material around the center mill roll, or for bonding of dissimilar stacked material passed through the mill. Three High Rolling Mills can also be .

A type of coldrolling mill, the tandem mill imparts greater strength, a uniform and smoother surface, and reduced thickness to the steel sheet. Unlike the original singlestand mills, a tandem mill rolls steel through a series of rolls (generally three to five in a row) to achieve a desired thickness and surface quality. Tantalum 5

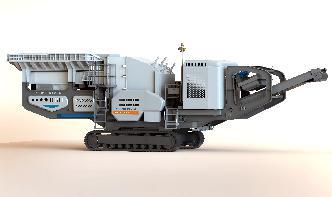

Steel Hot Rolling Mills Temperature Monitoring Temperature Control in Hot Rolling Mills. Hot Rolling Mills are used to reheat shapes of steel to soften them enough so that they can be rolled thinner and longer through a series of rolling stands. The finished product can be either a strip, plate, rod, bar, wire, or shape (rails and Hbeams).

ROLLING MILL ROLLS ____ Gerdau Summit manufactures Rolling Mill Rolls using modern methods and processes to ensure exceptional quality. With forged and cast options, our rolling mill rolls are synonymous with strength. Learn more:

Jan 10, 2008· Hi everyone, I wood like to share a different perspective on a Mc Donald rolling mill. The two rollers on the mill are 2 7/16 diameter. I have eliminated all pulleys and belts and substituted a 60 to one gear reduction box with a 3hp, 1140rpm motor and a 21tooth sprocket on the gearbox. The m...

The mill line is the heart of the heavyplate rolling mill. With rolling forces of up to 120 Meganewton, we have supplied the most powerful heavyplate mill stands worldwide. Our CVC ® plus technology is ideal for efficient profile and flatness control as well as increased mill productivity.

The layout of a rolling mill varies, from a simple single stand mill to several stands positioned either side by side or in a line. A mechanism, commonly called a roller table, directs the work piece to the rolls, and another roller table for handling the pieces emerging out of the roll. The table in front of the rolls forces the steel

Manufacturing and supplying roller guide box, gear couplings, pinch rolls, gear couplings for cold roll machine, hot cold rolling mill machines, reduction gear box for cold rolling machine, roller guide boxes, steel rolling mill stand, gear coupling, pinion stand, reduction .

Stretcher Temper mill Rolling defects Stretcher strains Cold rolled uncoated sheet Rolling defects Support roller imprints Cold rolled uncoated sheet Rolling defects Surface defect types in stainless steel Rolling defects Surface defect lack of material Rolling defects Surface defects of hot rolled steel plates Rolling defects

A ZMill or Sendzimir Mill is a machine for rolling a traditional rolling mill this 20high cluster mill configuration utilizes cascaded supporting rolls to apply force on the small work rolls in the center. This allows the application of a higher roll pressure without bending the work rolls, which would result in poor metal quality.

A reversing mill is a rolling mill in which the workpiece is passed forward and backward through a pair of rolls. The reversing mill is so named because the steel runs back and forth between the rollers, reducing the thickness incrementally with each pass. A reversing mill can be used to reduce material to gauge.

HOTROLLED STEEL. Hotrolling refers to a mill process in which you roll the steel at a temperature above its recrystallization temperature; a heat that typically exceeds 1000° F. When steel is heated past its recrystallization point, it becomes more malleable and can be properly formed and shaped.

offers 88 rolling mill looper products. About 4% of these are metal metallurgy machinery parts, 2% are rolling mill, and 1% are casting. A wide variety of rolling mill looper .

Mill Rolls. Kennametal manufactures mill rolls from cemented tungsten carbide grades tailored for the demanding environment of hot rolling mills that produce wire rod and seamless tube. We deliver mill rolls as unfinished blanks, semifinished rolls with ground inner diameter and thickness, or rolls .