AMT Materials and Processing. A particular component is attached to the aircraft structure by the use of an aircraft bolt and a castle tension nut combination. If the cotter pin hole does not align within the recommended torque range, the acceptable practice is to.

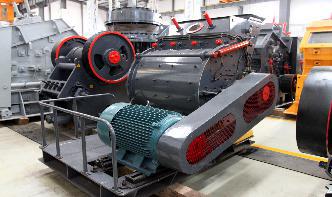

effect of heat treatment on steel ball crusher

Alloy Hammer At present, the common hammers used in the crusher are high manganese steel hammer and forging hammer, both of these two hammerheads are with the shortage of short using cycle, not wearresisting, high cost and low efficiency.

Spalling is caused by a granular weakening of the bearing steel. The failure begins as a small fracture of the steel's internal structure. This fracture progresses (propagates) to the surface of the bearing where particles of metal flake away. Noisy Running of the Bearing Because of the rough surface and the loosened metal chips there will

Sep 23, 2019· Heat treatment is acknowledged to have a considerable effect on the microstructure and mechanical properties of selective laser melting (SLM) parts. In this study, heat treatments were conducted on SLMprocessed WC/Inconel 718 composites with aim to .

Steel is such an important material because of its tremendousflexibility in metal working and heat treating to produce a wide variety of mechanical, physical, and chemical properties. Metallurgical Phenomena Thebroadpossibilitiesprovidedbytheuseofsteelareattributedmainly to two allimportant metallurgical phenomena: iron is an allotropic ele

The mechanical properties of steel decide its applicability for a particular condition. Heat treatment processes are commonly used to enhance the required properties of steel. The present work aims at experimentally investigating the effect of austempering and martempering on AISI 52100 steel. Different tests like microstructure analysis, hardness test, impact test, and wear test are carried ...

cryogenic treatment study on M2 tool steel, which involved a weeklong soaking, found only carbon clustering effect that resulted in increasing carbide density in the subsequent heat treatment [6]. Clustering of interstitial carbon at cryogenic temperature, as opposed to .

About Us Wuxi Orient Antiwear Co., Ltd. We are a specialized manufacturer of wear and heat resistant castings. Our main products are Mill Liners for Ball Mills,SAG Mills,AG Mills,Crusher Wear .

Castings can be manufactured from 500 grams to 15 tons. Skilled metallurgists select, customise and design material specifications and heat treatment programmes to suit specific products and applications. This ensures the optimisation of performance, product life, mechanical properties and ease of .

440C is a hardenable chromium steel. It has one of the highest attainable hardnesses of the corrosion and heat resisting grades. This grade is magnetic at all times. For those applications where superior machinability is desired and where slightly lower corrosion resistance is satisfactory 440C .

3. Sealing effect Though solid grease protects a bearing against ingress of foreign matters (water, dust, etc.), it is not an effective sealing device. Therefore, for applications that need reliable sealing performance, we recommend the use of contact type rubber seals (deep groove ball bearings, bearing units) or other seals (other bearing types).

Jun 09, 2001· Normalising. It may be used to break up the dendritic (as cast) structure of castings to improve their machinability and future heat treatment response or to mitigate banding in rolled steel. This requires heating to above the As temperature, holding for sufficient time to allow temperature equalisation followed by air cooling.

Apr 29, 2011· It has been reported that the impact energy of HEBM is typically 1000 times higher than the conventional ball milling The major use of the conventional ball milling is to fracture the particles and to reduce the size, while in high energy ball milling, a longer milling time can be achieved, which can help to activate and complete the ...

Oct 13, 2015· Carbon is the most important element in steel, it is essential in steels which have to be hardened by quenching and the degree of carbon controls .

for ore cone crushers. 2. Materials and Methods Babbitt alloys usually consist of a soft matrix and reinforcing phase inclusions. The phase (solid solution of antimony and copper in tin) is the matrix, and it provides good conformability and a special surface microrelief, which improves the supply of oil by friction sites and heat extraction.

Apr 01, 2002· The material in the vicinity of the ironchromium carbide is depleted of chromium and is technically no longer a stainless steel (in those localized areas that have experienced chrome depletion). The etching you see may be an effect of this processing .

Some studies about the effect of the shot peening process on the fatigue resistance, bending fatigue behavior, and residual surface stress in the ferritic stainless steels have been performed. However, the effect of the shot peening process on the corrosion and oxidation resistance of .

The principle methods of determining hardness of steel are the Rockwell, Brinell and Scleroscope Tests. HEAT TREATMENT An operation or combination of operations involving the heating and cooling ofa metal or an alloy in the solid state for the purpose of obtaining certain desirable conditions or properties.

PROPERTIES, IDENTIFICATION, AND HEAT TREATMENT OF METALS GENERAL PURPOSE ... steel, and the various steel alloys, The only difference between iron and steel is the carbon content. Cast iron contains more than 2percent carbon, while ... metal to be used and its heat treatment (if required). If no drawing is available, knowledge of what the ...

We are good quality supplier of Heattreatment Fixture, High Alloy Forgings, Centrifugal Castings from China. ... A Crusher for Crushing Stone EB19044. ... OD90mm 45 Steel Grinding Media Ball,Forged and Cast Grinding Steel Ball for Cement Mill,Low Price Grinding Steel Ball.

The commonly found h eat treatment problems in the heat treatment process. The heat treatment process is often the last or one of the last, but certainly in most cases one of the important steps in the manufacturing and production of metal parts, semifinished metal parts, and metal fore products for the production of the before mentioned products.