A new milestone has been reached on Fortescue Metals Group's (FMG) billion Eliwana iron ore project in Western Australia's Pilbara region with NRW Holdings being appointed as the contractor to deliver Stage One of the rail component of the project.

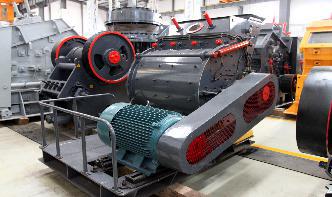

equipment to process iron ore holdings

Mining is the removal of valuable raw materials or other geological materials from the earth, from an ore body, vein or (coal) seam. The term also includes the removal of soil. Materials healthier by mining include base metals, precious metals, iron, uranium, coal, diamonds, limestone, oil .

Sep 08, 2014· Pelletization Prosess Pelletization is the process of making spheres of high carbon contains uniform quality iron ore. Necessity of pelletization The configuration of iron ore powder in the blast furnace is more tightly packed and restricts the air flow .For free air flow the powder of iron ore should be in spheres.

Roy Hill. Roy Hill has a defined mineralisation of more than of +50% Fe iron ore of which is +55% Fe, enough to sustain a mine life of more than 17 years. With integrated mine, rail and port facilities, which has the capacity to deliver 55Mtpa – Roy Hill is one of .

Charcoal is essentially pure carbon. The carbon combines with oxygen to create carbon dioxide and carbon monoxide (releasing lots of heat in the process). Carbon and carbon monoxide combine with the oxygen in the iron ore and carry it away, leaving iron metal. In a bloomery, the fire doesn't get hot enough to melt the iron completely. Instead, the iron heats up into a spongy mass containing iron and silicates .

Ironmaking and steelmaking Direct reduction, scrap processing, melting, refining and recovery plants. 1/6. RESET. Iron ore processing. ENERGIRON. Scrap shears. Shredder Plants. Baling presses 2015. Modern Blast Furnace Design. Hot Blast Stoves. Pulverized Coal ... SublanceBased BOF Process Control Hot Metal Desulphurization ...

this process, we have established a strong track record ... • In 2018, decided to develop South Flank iron ore mine in Australia as well as new iron ore deposits through ... • In 2016, invested in Panasonic Healthcare Holdings Co., Ltd. (currently PHC Holdings Corporation), a medical equipment manufacturer

Iron ore consists of oxygen and iron atoms bonded together to form the ironoxide molecule and needs to have the oxygen removed through smelting to create a purer iron product. During this process, the iron ore is heated to extreme temperatures in blast furnaces where lump ore is .

The need for iron ore pellets is directly connected to the steel production industry. Through the pelletizing process, iron ore fines are converted into spherical pellets, which are then suitable as feed material in blast furnaces for pig iron production. Imerys' bentonite .

The iron is removed through a selective precipitation process of the ferric iron at a controlled pH level. After the initial metal leaching process, the iron is present as ferrous iron, and an oxidation step is introduced to oxidise the ferrous iron to ferric iron for removal before precipitation.

Iron Ore Holdings is owned by Bruce Walter, the Chairman of Nunavut Iron, Jowdat Waheed, the President and Chief Executive Officer of Nunavut Iron, and funds managed by The Energy Minerals Group ...

Any ore particles you want, we can help you achieve. Advanced Technology Products. Adopt the most advanced technology to meet you highquality mineral services. High Quality Service. Sincere communication, considerate service, all best for you. MINERAL METHODS.

A wide variety of iron ore mining equipment options are available to you, such as gravity separator, magnetic separator, and flotation separator. MENU

Charcoal, iron ore, and limestone were introduced into the furnace in the charging area on the upper level. The blast equipment, which supplied air to the furnace, is located on the next lower level. This is believed to be the sole surviving example of this type of machinery.

Jul 23, 2007· SEVEN Network's billionaire chairman Kerry Stokes has taken a 12 million punt on Western Australia's iron ore sector with a deal to take control of Pilbara explorer, Iron Ore Holdings.

Another way to create steel from pig iron is the Bessemer process, which involves the oxidation of the impurities in the pig iron by blowing air through the molten iron in a Bessemer heat of oxidation raises the temperature and keeps the iron molten. As the air passes through the molten pig iron, impurities unite with the oxygen to form oxides.

metal iron content by directly reducing iron ore (or iron ore pellets) with reducing gases. While the produced DRI is mainly used as the raw material of electric steelmaking, it is also used as blast furnace feed for energy saving (reduction in coke consumption) and increased production of molten iron at integrated blast furnace steelworks.

Oct 26, 2019· Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal content. The process of iron ore beneficiation has two complementary goals and these define the methods used to refine it.