The subject grinding aid composition can have the ingredients separately introduced into the grinding mill. Preferably, they can be added as a dispersion of the carbon in glycol. A stable dispersion can be achieved by forming a mixture of the particulate carbon in the alkylene glycol and adjusting the pH of the mixture to at least about 8.

factors influence ore grinding mill

Impact in a mill can harm grinding media, causing cracking or breakage, if the media is not designed and expertly manufactured for the milling environment. A broken ball can still assist in ore processing, but the performance is significantly reduced and may have other negative effects. The .

Used in grinding ball mill all kinds of ores and other materials, and is widely used in dressing, building materials and chemical industry. China Fote Machinery always adhere to the high starting point, high standard, high quality production ball mill grinding process is affected by many kinds of factors, and the factors influence ...

The effect of grinding conditions on the response of an ore can be studied by varying one condition at a time and deducing information from the data [13]. Man [5] indicates that mill speed affects energy consumption and throughput. The ball size influence mill throughput, power consumption and progeny size [14], [15]. It is

The hardness, toughness, dissociation and structural defects of the ore determine the difficulty of grinding. If the grinding degree is small, the ore is easy to grind, the wear of the mill liner and the steel ball is smaller, and the energy consumption is also small; on the contrary, the wear is large and the energy consumption is high.

INFLUENCE OF COPPER ORE COMMINUTION IN HPGR ON DOWNSTREAM MINERALLURGICAL PROCESSES Crushing processes taking place in highpressure grinding rolls devices (HPGR) are currently one of the most efficient methods of hard ore size reduction in terms of the energy consumption. The HPGR products are characterized by a fine particle size and the

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 89. Pilot plant description. The milling pilot plant consists of two containers mounted on top of each other (see Figures 1 and 2). The bottom container holds the mill, the drive train, rollers and the hightension cabinet.

The spiral classifier is one of the important mineral processing equipment. The classifying effect of the spiral classifier will directly affect the content of the qualified product in the returned sand, thus affecting the grinding efficiency of the grinding mill.

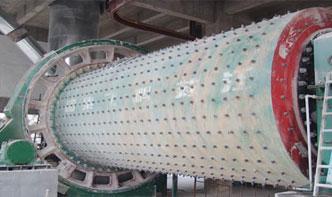

Wide Application of Ball Mill Ball mill, as the key grinding equipment of the materials, is widely used for mineral grinding such as cement, lime, quartz, slag, silica, iron ore, copper ore, gold ore, bauxite, calcite, barite, gypsum and other minerals in mining, quarry, chemical, cement and other industries Ball mill is the necessary equipment in ore beneficiation plant.

After primary and secondary grinding the ore was subjected to classification, the course fraction was recycled to the primary mill while the under size fraction was fed to the cyclone. The overflow of the cyclone was the flotation feed and the underflow was subjected to a secondary grinding step in the pebble mill.

Breakage rates of particles in a ball mill change with instantaneous particle size distribution in the mill. Slurry density and the presence of a grinding aid also affect breakage rates ..... Factors Affecting Breakage Rates in Batch Grinding.

Pendulum Roller Grinding Mill; Ultrafine Vertical Grinding Mill; Ultrafine Grinding Mill; ... Influence of physical properties of ore on working efficiency of crusher . Summary:There are many factors that affect the working efficiency of the crusher. Only a brief introduction is given to the physical properties of the ore.

Iron Ore Concentrator. Ore beneficiation technology is the science and technology based on physics, chemistry and biology and other disciplines, and it's divided based on the features and exist forms of selected minerals. Physical methods of ore beneficiation include common mineral washing, screening, reelecting, magnetic separation, etc.; while chemical beneficiation methods refer to the ...

Mechanisms of Grinding Modification by Chemical Additives: Organic Reagents. H. ELSHALL ... due to the influence of the adsorbing species ... gram studying the effect of fluidity modifiers on the performance of batch and industrial grinding mills, other workers [3 13] have adopted a third mechanism. The proposed

Dec 26, 2017· Several factors affect the efficiency of a ball mill for cement grinding. In this article, we shall be looking at some of these factors that have been proven to influence grinding efficiency: Mill Geometry And Speed. According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed.

There are many factors that influence the yield of MAIZE FLOUR MILLING MACHINE, such as the degree of corn crushing, equipment storage capacity, equipment processing capacity and uniformity of particles required for grinding corn, these factors will influence the yield of maize flour milling machine. Henan Food Machinery Manufacturing Co., Ltd. detailedly introduce the factors that influence ...

Ore around but because of the influence of the factors such as geographical environment, even the same ore its composition is also different, so in the choice of barite mineral grinding machine at the same time also want to consider the local geographical environment factors, make full use of the barite mineral grinding machine.

Because of the heavy wear and tear on machinery and the risk of fire from sparks to the dusty atmosphere, the lifetime of mills rarely exceeded more than 200 years before a new mill would be rebuilt over the same traditional site. Flint Mills. The process for grinding .

values. Therefore, in the application of the grinding model, the breakage rate parameter should be allowed to take on any value without applying any constraint. The subject of this paper is to study the effect of mill environment (particle size distribution within the mill) on the breakage rates in batch grinding.