Jan 01, 2016· Infeed grinding has been used by operators in grinding relatively complex parts. Unlike the throughfeed grinding process which pulls the workpiece past the grinding wheels, the workpiece in infeed is held and supported between the wheels for a thorough grinding even in .

in feed grinding process

Nov 13, 2012· Grinding for Feed. Nov 13, 2012 Tom Blacker | Advertisements. Check out this video on the grinding process in the poultry feed production by M. Baumann of . By: Marco Baumann. Grinding process in the poultry feed production. M. Baumann () Courtesy of

InFeed Grinding. InFeed centerless grinding is available for parts that have shoulders or obstructions not allowing them to pass in between both the regulating and grinding wheels. We have the capability to hold tight tolerances and ensure critical features are met per customer specification. We have the ability to perform infeed profile grinds...

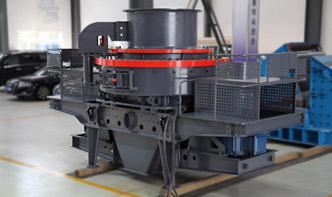

Infeed/Thrufeed Centerless Grinding Systems From manual to fully automated, our modular GT610 Series of precision Infeed/Thrufeed Centerless Grinders are able to remove more material faster, and with better surface finishes, than competing machines.

There are many different methods for processing feed for pigs. In addition to grinding, the most common forms of feed processing are pelleting, extruding, and roasting. Pelleting. Pellets can be made of different lengths, diameter, and degree of hardness. The ingredients of the diet will influence the hardness of the pellet and pellet quality.

Grinding or particlesize reduction is a major function of feed manufacturing. Many feed mills pass all incoming ingredients through a grinder for several reasons: (a) clumps and large fragments are reduced in size, (b) some moisture is removed due to aeration, .

The grinding feed mill automation process increases efficiency and improves conditioning in a feed production operation. Grinding performs particle size reduction for further processing of the material. Grinding creates more surface area which aids in digestion of the feed. In the grinding process fracturing of the solid material occurs, resulting in both an increase in material surface area and dissipation of heat.

The centerless process is commonly used for high volume production, and it's also easily used for low volume production because the machine setups are fairly simple. In thrufeed centerless OD grinding the workpiece passes between two wheels, a grinding wheel and a regulating wheel (as illustrated in the diagram below). Both wheels rotate in the same direction, but at much different speeds.

creep feed grinding Creepfeed grinding is generally used to describe a surface grinding operation performed in a single pass with an unusually large depth of cut. Generally, the creepfeed grinding process is marked by a special mode of operation.

Centerless Grinding Wheels Achieve extremely close tolerances with Norton centerless grinding wheels. Whether through feed, end feed or in feed grinding, our centerless grinding wheels give a .

Abstract: This paper examines the value and character of cutting forces in the creepfeed surface grinding. In order In order to identify the impact of cutting forces on the state of the process of deep grinding, according on the elements of the

Creep feed grinding is a recently invented process of material handling. It combines high quality of the piece surface, productivity, and the possibility of automatic control.

The job of an animal nutritionist is to make sure the diet is balanced and meets the nutritional requirements of the specific animal species or animal group. Many animal nutritionists work with or in feed mills. The relationship between the nutritionists and the feed mill operators and managers is .

Different grinding methods, grinding intensities, and thermal treatment processes are used to achieve an efficient feed production and to increase the quality and safety of feed (Cox et al., 1986; Edwards, 1999; Peisker, 2006). Feed production and processing may affect gastrointestinal morphology and function.

Infeed centerless grinding is used to grind workpieces with relatively complex shapes, such as an hourglass shape. Before the process begins, the workpiece is loaded manually into the grinding machine and the regulating wheel is moved into place.

ThroughFeed Grinding. In throughfeed grinding, the part rotates between the grinding wheel and a regulating wheel as shown below. For throughfeed grinding, one or both wheels of the centerless grinding machine are canted out of the horizontal plane, as shown below. This imparts a horizontal velocity component to the work piece,...

Creep feed grinding Manufacture: An effective grinding process which combines a high rate of stock removal with... Materials: Although the process can be used for grinding materials that can be ground by conventional... Design: Process is capable of machining components of similar design to those ...

Welldesigned grinding processes usually enhance workpiece surface quality producing low roughness, compressive or neutral residual stresses and improved fatigue life. Grinding is a very efficient process for machining hard materials and has the potential to achieve high accuracy of shape and size.