Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing,

iron ore concentrate upgrading process

The aim of this study is to obtain pilot scale froth flotation process parameters to upgrade the Itakpe iron ore sinter grade to a superconcentrate that meet the physical characteristics of less than 30% passing 45 µm that will not pose transportation and handling problems at DSC. The

separator units to upgrade the ore and ultimately achieve a high iron grade (>65%) magnetic concentrate. The Ukra inian Underground mine is ca lled Artyom and it is basically a hematitic ore, wit h

Iron concentrates obtained by the dry method are susceptible to spontaneous combustion because of the air already trapped within the concentrate during the crushing process. Due to dampness within the cargo, the sulphur can react with the oxygen to produce heat, resulting in spontaneous combustion.

that uses iron ore concentrates that are plentiful in the United States. The process would use inexpensive, abundant natural gas (or hydrogen) to both heat the ore in the furnace and to remove oxygen, converting the ore to iron metal. Although similar to Direct Reduced Iron, this advance would process fine powder

Improvement of mechanical strength of iron ore pellets using raw and activated bentonites ... obtained when bentonite activated with 3% sodium bicarbonate was added at an amount of 4%. The effects of sodium bicarbonate on the activation of upgraded calcium bentonite were tested individually.

After the upgrade, the iron content in the final iron ore concentrate was shown to be significantly higher. Remarkably, the costs for employing the respective measures are surprisingly low. This case study is based on a Kazakh iron and steel producer, whose beneficiation process is currently generating a magnetite concentrate with a final iron content of per cent.

Magnetite ore is further processed through magnetic separation, an important process in producing magnetite iron concentrate. Concentration includes all the processes that will increase (upgrade) the iron content of an ore by removing impurities.

Iron ore concentration When used at concentration plants with combined methods of cleaning, the process of dryconcentration at initial stages makes it possible to substract up to 50% of dry final tailings.

we are mainly deals with production of ultra pure iron concentrate,raw iron ore and its related mineral separation process. Iron ore concentrates are used as a metallurgic raw material in iron smelting with grade between 70 and % Fe. Iron ore concentrates are .

Abstract. The basic characteristics of Australian iron ore concentrate (OreA) and its effects on sinter properties during a highlimonite sintering process were studied using microsinter and .

Oct 01, 2013· Sustainable Processing of Iron Ore. Clariant Mining's FLOTICOR³ PA 8000 improves the pelletizing process. • Higher production • Higher iron content • Lower energy • Robust pellets.

Heavy media separation, Iron ore, iron ore beneficiation, Jigging, magnetic separation, washing, Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth's crust averaging from 2 % to 3 % in sedimentary rocks to % in basalt and gabbro.

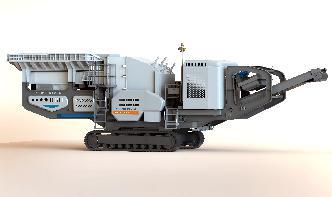

Jan 27, 2013· iron ore to concentrate process – Crusher South Africa. process of upgrading iron ore ore concentration plants and Main Process Equipment . Search iron ore concentrate process to find your need. »More detailed

Certain material types currently considered to be uneconomic were upgraded using the dry magnetic cobbing process to produce a millable ore concentrate. Best magnetic iron recoveries after cobbing ranged from approximately 78 to 95 pct for the Tertiary feed .

Nov 30, 2017· Fortescue to upgrade iron ore. By Houses and Holes in ... Magnetite processing is a wet process. No dust! ... there is a case for making a concentrate that sells for US90 per tonne if it can be ...

Freelance Modernization of mining ore plant in Ukraine results in increase in production effectiveness Project brief At Ingulets GOK's large investment project in Kryvyi Rig, Ukraine, in Phase 2 of the magnetic flotation concentrate finishing process the entire magnetic flotation technology department manages the process using a complete

Iron ore can be upgraded to a higher iron ore content through beneficiation. This process generates iron ore filter cake which needs to be pelletized to be used in the steel making process. Also during the processing of high grade iron ores which don't need beneficiated, fines which are generated can be pelletized and used instead of being disposed of.

Arzesh Holding Co. seeks to meet its need to concentrate as raw material, intend to build a plant with a capacity of 5 milion tons of iron ore concentrate in two phases. OUR Collaborators The BSIET (Bejing Shaugang INternational Engineering Technology) as are Project EPC Contractor

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of .

<9% cake moisture for iron ore concentrate is possible without addition of reagents, but depends on several factors: type of filtration equipment (vacuum or pressure filter), PSD of feed slurry, % feed solids, and type of iron ore, among other factors.

Process Introduction. The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involved. However, these single separation methods can not help to get ideal beneficiation .

Nov 30, 2017· Fortescue to upgrade iron ore. FMG blends its various quality ores to reach its high volume output of 58%. If it's going to aim for 62% then by definition it's salable volumes are going to fall as higher quality ore can't be cut with lower.