for separation of magnetite ore. It provides separation of mineral complexes according to magnetic properties, density and size. Magneticgravity separators (MGS) have been designed and their parameters are defined, It has been shown that MGS enables to obtain % improvement in Fe

iron ore magnetic separation

Titanomagnetite is an ore of iron and titanium, and is highly magnetic. Magnetite and ilmenite are two major minerals. Ilmenite exhibits various textural dispositions. Widmanstatten and granular exsolution textures are important ones exhibited by the constituent mineral.

There are a lot of iron ore in nature, which containes highly quantities of hematite or mainly iron ore beneficiation method is magnetic separation and flotation separation,so the mainly used iron ore equipments are flotation machine, magnetic separatior,efficient thickener,press filter,slurry pump,feeder, agitation tank and belt conveyor etc.

Magnetic ore separation plant, Edison (now Ogdensburg), New Jersey, c. Iron Ore Magnetic Separation 911 Metallurgist Some time in the, year 1887 my attention was called to the magnetic separation of ores.

May 26, 2016· New dry iron ore processing technology developed. As iron ore must be composed of grades of at least 58 per cent, mining companies stack the lower grade material on tailings dumps. This material with low iron content is then processed and iron is separated from other materials, particularly silica (sand), from these stacks.

The recovery of fine iron ore by magnetic separation will decrease with decreasing particle size because the magnetic susceptibility of magnetic particles decreases with a decrease in particle mass. There is an example of an Australian ironore operation that introduced beneficiation of fine haematite, .

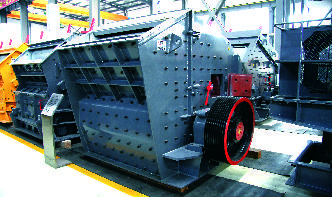

Iron Ore Extraction Process or Beneficiation Of Iron Ore, Iron ore processing plant is a relatively simple processing solutions that mainly used for iron series mimerals, such as magnetite, river sand, quartz sand and slags. the key equipment that used for a Iron Ore Beneficiation Plant is Ball Mill and Magnetic Separator.

iron ore beneficiation flotation or magnetic separation. Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation.

Magnetic Separation of Iron Ore Iron ores should be of a good grade (above 65% Fe) to be used in blast furnaces. Lowgrade ores are usually beneficiated/upgraded. Beneficiation technique for iron ore is important in order to achieve a maximized utilization of ore resources and to .

Fatma et al. (1999) studied the beneficiation of an iron ore sample containing 44% Fe, % SiO 2 and 20% BaO. By magnetic separation, two products of iron ore and barite concentrates were obtained by using a high intensity magnetic separator. The fine fraction ( mm) is about 20% by weight assaying % Fe, and %

The ore powder after magnetic roasting is subjected to a multistage lowintensity magnetic separation (LIMS) process to obtain highgrade iron concentrate products. Materials such as coal, natural gas, coal gas, and combustible exhaust gas can be used as fuel for this process [ 5 ].

As one kind of magnetic separation equipment,Magnetic Ore Separator are designed for sorting and preseparation of low grade iron ores, raising ore grade and reducing production cost. They are suitable for using in arid regions that short of electric power because they did not need water resource and even can be driven by diesel engine.

Separator Magnets. PERMANENT MAGNETIC PULLEY Used for applications such as iron ore cobbing, slag processing, mineral beneficiation, auto shredding, blue box recycling, aggregate processing, food processing, etc. ELECTROMAGNETIC SUSPENDED SEPARATOR Selfcleaning and designed to remove large and small tramp metal from conveyors.

Magnetic separation has two major applications in mineral processing plants: The removal of tramp iron (which would deleteriously affect subsequent processes) from an ore stream This is usually achieved by a low intensity magnet suspended above, or at the head of, a conveyor Separation of magnetic minerals from less magnetic minerals...

of Iron with gangue minerals [5]. Magnetic separation using wet highintensity technique has become one of the most suitable methods for recovery of iron from lowgrade ores [6], due to its better separation efficiency as compared to dry magnetic separation and gravity separation [7]. Flotation processes using

ore utilising dense media separation (DMS), jigging, wet magnetic separation, dry magnetic separation, flotation and xray processing. Another group of iron ore projects involve the mining of hematite ore below the water table.

Iron ore beneficiation plant flow: The iron ore is preliminarily crushed by jaw crusher,after crushing to a reasonable size through lifting machine, feeder evenly into the ball mill for crushing, grinding. After the grinding of ball mill the fine ore material is expected to enter the next process: classification.

Magnetic separation technologies are used to take the advantage of the difference in the magnetic properties for separating iron ore from the non magnetic associated gangue materials. Magnetic separation can be conducted in either a dry or wet environment, although wet .

Nov 05, 2016· Analysis of Wet HighIntensity Magnetic Separation of LowGrade Indian Iron Ore using Statistical Technique, Separation Science and Technology, volume 47:8, Pages . Pradip "processing of alumina rich iron ore slimes" mineral processing and Engineering2003.

Magnetic separator for iron ore introduction: Magnetic Separator is suitable for wet magnetic separation of materials less than 3mm such as magnetite, calcined ore, etc. Magnetic separator for iron ore structure: Its magnetic system is a ringshape chain closed magnetic circuit with energizing coils made of copper tube and cooled internally by water.