First, iron ore is mixed with coke and heated to form an ironrich clinker called 'sinter'. Sintering is an important part of the overall process as it reduces waste and provides an efficient raw material for iron .

iron ore refining process

pyrometalurgy. The lead reduction smelting process involves twosteps: a fusion of the ore material with lead in a carbonrich environment, followed by the separation of silver from the lead in an oxygenrich environment. Period metallurgists used a variety of fluxes, elevated temperatures, and the principle of

The smelting and refining process for iron and steel in the BFBOF process involves the carbon reduction of iron ore (Fe 2 O 3) in the BF to make molten iron, and decarburization of molten iron in the BOF to make molten steel. Major reducing agent in the BF is the carbon monoxide gas (CO) generated by the oxidation of the carbon (C) in coke.

Smelting is the process of refining the iron ore into useable purer iron. Here is where some chemistry gets involved. Starting with the iron ore, you want to remove the impurities and deoxygenate the ore so you are left with only iron atoms.

May 19, 2013· Also I am wondering whether or not the crumbly ore i have now, as a result of simply placing the iron ore onto the top of the charcoal, is worth keeping and can it be refined more. Ive decided to have a go at changing my forge into a rough furnacebloomery and try to use an improvised tuyere for any slag, can someone please explain the process ...

As with the copper refining process, the oxygen released by the iron was used up in the combustion of the carbon monoxide, which added heat to the fire and helped the reduction of the metal to proceed.

Sep 18, 2011· This modern process for extracting iron ore from taconite and refining concentrate into pellets is a direct result of Dr. Davis' research funded by the IRRRB: First, holes are drilled and the taconite ore is blasted out of the ground.

Jul 26, 2019· While Britain had good iron ore reserves, the iron produced was of low quality with plenty of impurities, limiting its use. There was plenty of demand but not much was produced as wrought iron, which had many of the impurities hammered out, took a long time to make, and was available in cheaper imports from Scandinavia.

The new plant crushed the ore into smaller pieces to remove more gangue, and then roasted it in rotary furnaces to reduce the sulphur content. In 1982, we added a magnetic separation process to improve the refining process further. The result was a richer titanium slag, with nearly ten per cent higher levels of iron and titanium oxides.

In the Outotec® Fire Refining Process, the hot blister copper is charged into an anode furnace for purification. The refining is carried out in batches where the necessary oxidation and reduction stages are used to purify the copper.

Metalcess usually recommends goethite precipitation for iron removal in zinc hydrometallurgy. To maximize the value of goethite residue, Metalcess developed flash magnetization roasting technology in the aim to recycle goethite generated in the iron removal process of zinc leaching. It can enrich the goethite residue into standard iron ore for sale.

The Ore Extraction and Refining Process Before iron ore can be used in a blast furnace, it must be extracted from the ground and partially refined to remove most of the impurities Leaning on his long tongs, this young iron puddler's helper posed for this photograph in the early 1860s, when the Sons of Vulcan was a young union ...

Meet the Instructors. This is called Electric Arc Furnace process. In Electric Arc Furnace, raw material for iron is not ore or coke, but it just directly uses scrap. Once scrap is made from Electric Arc Furnace, then it undergoes, secondary fine process and casting process. Now, let's look at the graph right inside,...

Metal from Concentrated Ore. The next step in the extraction of zinc is called Roasting. The concentrated ore is finely ground into small pieces and then suspended in a rising stream of air. The sulphur content can be reduced hugely with this process. This also converts the Zinc Blende to ZnO which is way more reactive. The reaction occurring here is

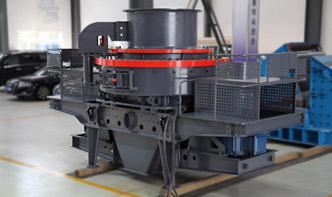

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore. Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding .

Copper refining is done by the electrolytic process. Its impurities of iron and zinc will dissolve in the copper sulphate solution. And its other impurities of gold or silver or platinum will remain behind. Zone Refining. Zone refining is a special method we use to purify metals. It was the invention of William Pfann.

Copper Refining: From Ore to Market. This crucial process, which is generally conducted at or very near mine locations (to save on transportation costs), involves grinding mined ore to roughly separate copper from waste rock. The copper is concentrated further by .