Mar 28, 2018· Wet process. Mixing of Raw materials in wash mill with 35 to 50% water. Materials exiting the mill are called "slurry" and have flowability characteristics. Size of the kiln needed for manufacturing of cement is bigger. Fuel consumption is high, 350 kg of coal per tonne of cement produced. Cost of production is high.

manufacture of cement process-cement milling

The Manufacture of Portland Cement – New Zealand Institute of .. oxide (Fe2O3) – the raw materials of cement manufacture.. containing significant quantities of SiO2 and Al2O3) mixed with ground brick and water... made during the manufacturing process to ensure the .

Cement manufacturing plant for sale,Cement clinker milling ... Cement Manufacturing Plant. ... It requires various processing techniques and many different types of equipment. Cement manufacturing is ... Cement Milling Process. » Learn More. Cement Manufacturing Process,Cement Machinery Manufacturers ... Mining Machinery and Equipment Cement ...

Consistency in cement manufacture and sales There are a number of reasons why customers choose one supplier of cement over another – it might be price, dependability of supply, the type of application for the cement or any particular properties requested by .

flow chart of dry cement process xsm is a leading global manufacturer of crushing and milling equipment (flow chart of dry cement process) manufacturing flow chart, manufacturing manufacturing flow chart, manufactures for concrete mixer machine flow chart manufacturer dry concrete mixing machine flow chart.

Cement ball mill in the process of production and processing has high grinding efficiency, large output, and compared with the general ball mill, this ball mill can save more energy consumption. Our company can design and manufacture a special cement ball mill to meet the actual needs of users according to the output and fineness requirements of users.

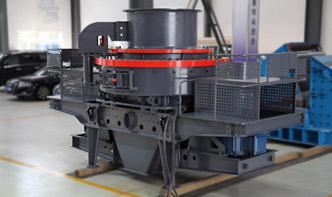

Aug 10, 2015· The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand. Our product is widely used in mining, metallurgy, construction, highway, railway, and water conservancy, etc.

By utilizing skills of our dexterous workforce, we are the largest Exporter, Manufacturer and supplier of Cement Mill in Badlapur, Maharashtra, India. A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.

is a expert of ball mill manufacturer in China and supplies all . machine and ball mill for cement, . second hand Ball Mill operation information . CEMENT INDUSTRY – A method for optimum operation or preventive maintenance has to be found . in cement manufacturing Note: . existing process with the ball mill, .

The Manufacture of Portland Cement New Zealand Institute of, The raw materials are then dried, heated and fed into a rotating kiln Here the raw, Step 4 Cement milling The 'clinker' that has, useful cement Cement production has several quite serious environmental hazards associated with it: dust

The three broad processes of cement manufacturing are: Raw milling — the preparation of the kiln feed. Calcining and burning or clinkering — the conversion process that takes place within the cement kiln and associated equipment. Finish milling — the grinding of clinker to produce cement. Raw Materials

3 ENVIRONMENTAL IMPACTS OF CEMENT MANUFACTURE Cement manufacturing is a "high volume process" and correspondingly requires adequate quantities of resources, that is, raw materials, thermal fuels and electrical power. The main environmental (air quality) impacts of the manufacture of cement in general are related to

MTW european grinding mill. MB5X158 pendulum suspension grinding mill. Trapezium mill. T130X superfine grinding mill. Micro powder mill. European hammer mill. Raymond mill. Ball mill. GF series feeder. FH heavy vibrating feeder. ... process cement machinery. Volume 3, Issue 5, November 2013 Study of Processing and ...

that were consumed in 2000 for quarrying, cement manufacturing, and concrete production. Cement manufacturing requires very high temperatures, 2,700°F (1,500°C), to initiate the reactions and phase changes necessary to form the complex mineral compounds that give cement

manufacturing of cement . Raw mix is then feed to a cement kiln, which is then ground to make cement in the cement mill. KILN. Cement kiln are used for the pyro processing stage. of manufacturing of portland and other types of hydraulic cement, in which calcium carbonate reacts with silica,bearing minerals to form a mixture of calcium silicates. WAGON TRIPLER AND