It acts as main filler, and forms the main bulk of concrete, around the surfaces of which the binding materials adhere in the form of film. Broken stone, broken bricks and gravel are generally used as coarse aggregates. The crushing strength and water tightness of concrete and its resistance to wear and tear depend upon the aggregates.

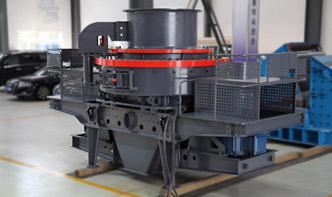

manufacture process of coarse aggregates

natural coarse aggregate, natural fine aggregate and RCA. Natural coarse aggregate used is microtonalite with maximum size of 25 mm. Natural fine aggregate used is river sand and RCA used from demolished concrete waste from which physical test such as specific .

Adescribe The Process Of Manufacturing Of Aggregates Aggregates, which comprise 75 percent of concrete by volume, improve the formation and flow of cement paste and enhance the structural performance of concrete. Fine grade comprises particles up to. 20 of an inch (five millimeters) in size, while coarse grade includes particles from. 20

Easily share your publications and get them in front of 's millions of monthly readers. ... A review paper on use of recycled concrete aggregates in concrete manufacturing process ...

North Europe. The manufacturing process of these aggregates requires pelletizing a mixture of the fly ash and water before sintering the pellets at 1300oC. This process produces light spherical aggregate with high proportion of voids. The manufacture of sintered pelletized aggregate from

Mar 28, 2018· I've said this in my previous posts as well. If you're an end consumer using the block for a construction then all you should be bothered about is the basic field tests and see if they pass the criteria. If you're asking to know about the manufact...

Nov 15, 1988· A process for the production of coarse scrubbing aggregates of titanium dioxide particles by vapor phase oxidation of titanium tetrachloride with an oxygencontaining gas thereby forming a hot gaseous reaction mixture containing suspended TiO 2, previously recovered coarse TiO 2 scrubbing aggregates being commingled with the hot gaseous reaction mixture, the hot reaction mixture being .

(2) The production of expanded blast furnace slag is no longer favored and is being replaced by the pelletizing procedure. ACBFS has been used as an aggregate in Portland cement concrete, asphalt concrete, concrete, asphalt and road bases. Pelletized blast furnace slag has been used as lightweight aggregate and for cement manufacture.

Construction aggregates are produced from naturally occurring mineral deposits, including solid rock formations such as limestone and granite, and from loose deposits of sand and gravel. The most common structural uses of construction aggregates include the coarse and fine mineral components in Portland cement concrete and asphalt.

Apr 18, 2019· White cement concrete is similar to that of grey Portland cement but differs in fineness and color. The white color of this cement is determined by its manufacture process and its raw materials. This cement allows a wide range of color options for producing architectural and structural concrete.

For fine aggregates, river sand is used on a large scale. The dividing line between fine and coarse aggregates is mm sieve size. Particles passing through the sieve are categorized as fine aggregates. Sand should be clean without silt or clay, salt and other organic materials and should neither be too fine nor very coarse.

12 mm. Primo Coarse Aggregates is also known as Blue metal, Jelly Stones or crushed stone. It is the fillers in concrete acts as one of the load bearers. Coarse aggregates are available in different sizes ranging from 12mm, 20mm,40mm.

These IS codes include the Standardization in the field of all types of cement, pozzolana, testing sand, concrete, aggregates, instruments for cement and concrete testing, cement plant machinery and ferrocement concrete, reinforced concrete and prestressed concrete, test methods for concrete, concrete production and execution of concrete ...

This specification is for coarse aggregates, intermediate aggregates, fine aggregates, mixed aggregates (both coarse and fine material) and miscellaneous aggregates for use in all types of concrete construction. REQUIREMENTS a. Coarse Aggregates for Concrete. (1) Composition. Provide coarse aggregate that is crushed or uncrushed gravel, chat, or crushed stone.

of aggregate (constructiongrade crushed stone and sand and gravel) was produced for every person in the United States. There are nearly 10,700 construction materials quarries and mines in the United States (4,000 crushed stone operations and 6,700 sand and gravel operations).

Aggregates, which comprise 75 percent of concrete by volume, improve the formation and flow of cement paste and enhance the structural performance of concrete. Fine grade comprises particles up to. 20 of an inch (five millimeters) in size, while coarse grade includes particles from. 20 to. 79 of .

High capacity efficient screening solutions reduce your operations costs and headaches. The EcoStar® provides sizing of high volume, bulky materials in the smallest footprint possible. BIVITEC® provides the ability to handle and remove high moisture organic fines from your process.

Aggregate Production Operations : How to Register TCEQ, If you own or operate a quarry, sand pit, gravel pit, or other aggregate production operation (APO) in Texas, you must register your APO with our water quality program [Live Chat for help] plastic manufacturers guide of Rotational molding process

Krishna Stone Crusher Manufacturer of Coarse Aggregates Concrete, Coarse Aggregates Concrete 40mm Coarse Aggregates Concrete 20mm from Jodhpur, Rajasthan, India. Krishna Stone Crusher Manufacturer of Coarse Aggregates Concrete, Coarse Aggregates Concrete 40mm Coarse Aggregates Concrete 20mm from Jodhpur, Rajasthan, India.