in the white cement industry, where consistency in brightness and tone are principal concerns. The color of white cement depends on both the raw materials and the manufacturing process. Metal oxides (iron, manganese, and others) that are present in the finished material .

manufacturing process cement pdf

Water plus cement plus aggregates. The formula seems simple, but the reality of concrete manufacturing is far more complex. The development of formulas for concrete requires very advanced scientific skills. The quality of the ceme...

Cement Manufacturing Process, Cement Bricks Factory ... The Wonder Cement factory process is now complete. From blasting the limestone to packaging the product, every stage of production is carried out with the utmost attention to detail so that every sidewalk, every school, and every city built on Wonder Cement can enjoy 'Ek Perfect Shuruaat'.

Steelmaking is the process for producing steel, heating iron ore and scrap steel in a furnace with oxygen. Temperature measurement during this process is essential for energy savings and quality control.

The cement itself can either be a pure hydraulic cement or a mix of hydraulic cement and SCM. Concrete mix recipes vary, but most have compositions (in volumetric terms) in the range of about: 7%–15% cement powder, 15%–20% water, %–8% air, 25%–30% fine aggregates (, sand), and 30%–50%

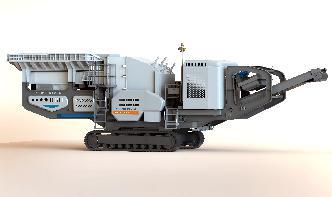

cement manufacturing process All operations of feeding of raw meal, coal, burning, temperature control and cooling are automatic through fuzzy logic / computer control. These operations are controlled from Central Control Room (CCR) which is the nerve center for any cement plant.

the overall production process of cement factory pdf. produce only cement and 2 produce only clinker [1]. Cement Production – The manufacture of cement is a twostep process, notably, clinker production and cement grinding. In the first step, the raw materials are fed to the kiln system to produce clinker.

The process of manufacturing of bricks is carried out in a number of stages. These are listed below. Each stage has its own specific importance. Stage 1. Selection of the suitable type of Brick Earth. Stage 2. Preparation and Tempering of Mud. Stage 3. Shaping or Molding of brick units. Stage 4. .

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

The clinker manufacturing process. The burning phase takes place in a rotary kiln. The clinker temperature in the kiln burning zone has to reach 1,500°C and then it is cooled in a cooler by air which decreases the temperature. The entire manufacturing process is continuously monitored and controlled from the central control room.

amounts of cement needed can be achieved by partial substitution of a pozzolan such as fly ash. Besides reducing cost, pozzolans help control efflorescence. Mixing it up The manufacturing process is a very precise operation with many quality controls to ensure production of a highquality product. One of these controls requires that the raw materials, in

Manufacturing Process Of Cement From ... lime stone crushing,grinding,packaging process in cement manufacturing It is a ... grinding mill in quarry and ... Manufacturing process flow Messebo Cement Manufacturing process flow . Messebo Cement Factory Pdf >>Chat Online; cement process with li ne dryer

Download free ebooks at Manufacturing Processes and Materials: Exercises 14 Question 2: The Electrodischarge Machining (EDM) process. Question 2: The Electrodischarge Machining (EDM) process. a) The Electrodischarge Machining (EDM) process is widely used m the toolmaking industry.

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone.

Jul 26, 2016· Aggregates are coarse materials like gravel, sand or crushed brick that are added to the cement and water. The cement binds to them, holding them in place. Although aggregates are often thought of as a filler, they're actually a key component of concrete. Between 60 and 80 percent of concrete is made of aggregates.

The Wonder Cement factory process is now complete. From blasting the limestone to packaging the product, every stage of production is carried out with the utmost attention to detail so that every sidewalk, every school, and every city built on Wonder Cement can enjoy 'Ek Perfect Shuruaat'.

Ramco Process Manufacturing is a flexible, fullyintegrated, adaptable and futureproof business solution that helps process manufacturing industries remain competitive in a changing marketplace. It supports an entire range of industry processes and operations including procurement, production, quality management, inventory

geopolymer cement concrete would necessitate changes in the process before scaling up production from bench scale to plant scale. The experience of manufacturing the precast concrete insulated panels for the concrete house is presented here as a case study of fullscale production in a plant. First, a description of the geopolymeriza

The application of the modern technology has made the production of cement by dry process more economical and of superior quality. Following is the procedure of manufacture of cement by the dry process using modern technology: (a) Most of the cement factories are located very close to the limestone quarries. The boulders upto m size are ...

For details about Basic Process of Cement Manufacturing, refer toCement Manufacturing Process

2 Cement Manufacturing process and Quality control Methods. Topics: 3 Topics Cement definition Types of cement Various cements Cement plant Machinery Various process of cement manufacturing Cement raw materials and Fuel Quality Control Parameters Applications of Cement Types Quality control tips Question and Answer session