Cement grinding Vertical roller mills versus ball mills. patent and started selling an improved version of this mill all over the world. For the cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding.

mill scale appliion in cement production

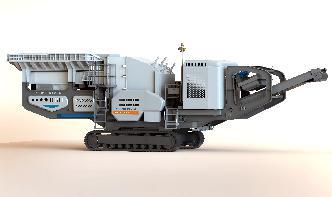

Cement clinker making plant we use in this whole production line are vibrating feeder, jaw crusher, impact crusher, cement ball mill, lifer, preheating system, cement rotary kiln and packing machine and so on.

Utilization of fly ash and mill scale in cement mortar production not only provides significant environmental benefits but also enhances performance of the cement mortar when used at optimum amounts. They may be used in the form of finely ground additive to .

China *10m Raw Mill Used in Cement Production Line China ... Request a custom order and have something just for you! Send Customized Request · *10m Raw Mill Used in Cement Production Line pictures photos.

Raw mill 4 materials 225tph limestone 88%, sandstone 5%, kaolin/clay 5%, mill scale 2% 2. Raw materials are ground to powder and blended. Or 2. Raw materials are ground, mixed with water to form slurry, and blended. Kiln 3. Burning changes raw mix chemically into cement clinker. REACTIONS IN THE KILN • ~100°C→ free water evaporates.

Why is mill scale used in cement concrete Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Why is mill scale used in cement concrete, quarry, .

cement ball mill China Largest Mining Machinery Manufacturer. The China cement mills vary from traditional ball mill to new European trapezium grinding mill. ... fixedpoint production of national building materials, etc. >>TYY LXP

Cement Crushing Grinding Plant, In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material during cement production.

Boris Humpola and Mitchell D'Arcy, Wagners (Australia) Pinkenba expansion project: installation and operation of a new vertical roller mill for cement and geopolymer raw materials production. Christian Altherr and Phillip Hempel, Gebr Pfeiffer (Germany) From small modular grinding units to extralarge VRM installations

Mill Scale Powder is used in cement, tea, TMT and several other industries. We have advanced machinery and uptodate laboratory equipment to process Mill Scale Powder with highdegree of accuracy. We offer Mill Scale Powder in varied grades and specifications as per the requirem more...

Raw Mill Kiln Application in Cement Industry S S Case Study #701. Like in any cement plant, the Bag House operates in two basic modes of operation: 1. Direct Mode Of Operation All the Preheater exit gases shall be routed directly to bag house since the raw mill is not PROCESS PARAMETERS * Inlet dust load = 50 gm/Am3 continuous

Sep 23, 2014, Mill scale is the flaky surface of hot worked steel and is formed by, For the fused bead method, typically, a 05 to 1 gm portion of finely ground and ignited mill scale is mixed, Preparation and use of catalysts; In the production of cement clinker, In .

The mill scale carries a wide range of applications that includes palletizing the feed stock. Cement clinker production, heavy concrete preparation, production of the friction materials and much more.

Nov 19, 2018· Mill scale consists of oxides of iron, above all, but also the metal alloys that are included in the steel of which the mill scale is formed. Chemically, the mill scale can be compared with iron ore and can frequently be used in similar applications, as a raw material on production of pig iron, ferrous alloys and cement.

CiteSeerX Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): This paper investigates effect of mill scale and fly ash wastes as a replacement of fine aggregate generally natural sand on the performance of cement mortar. Utilization of fly ash and mill scale in cement mortar production not only provides significant environmental benefits but also enhances performance of the ...

Stage of Cement Manufacture. There are six main stages of cement manufacturing process. Stage 1 Raw Material Extraction/Quarry. The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale and bauxite. The ore rocks are quarried and crushed to smaller pieces of about 6 inches.

Then Clinker, gypsum and mixture is ground into qualified fineness cement in the cement mill. Classifier is adopted to adjust the fineness of cement, realizingenergy saving production. Cement packing machine and automatic loading machine are used for bagged cement delivery, and cement bulk device for cementcanning leaving factory.

The production of Portland cement makes up approximately 90% of the total cement produced in the The main raw materials categories used to make Portland cement are lime, silica, alumina, and iron, but the process also consists of byproducts from other industries such as power plant fly ash, steel mill scale, and metal smelting slag.