Apr 19, 2014· In this paper, the spalling causes of backup rolls in a roughing mill of a hot strip rolling mill were investigated. The roughing mill withstood extreme service conditions with long service cycles for backup and work rolls, a large variety of the same width rolling campaigns, severe and non‐uniform wear contours of backup and work rolls.

rolls specifiion of 4 high reversing roughing mill

A twintandem reversing roughing mill has been realized as well which combines the advantage of a short roughing mill and a high throughput. On the other hand, this solution asks for a more sophisticated process control. The roughing stands may be built as twohigh or fourhigh mills, oneway, reversing, single or tandem configuration.

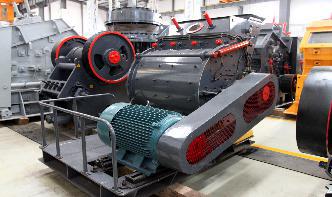

Roughing Rolling Mill Stand. The roughing mill stands are used to reduce the thickness of the steel while at the same time extending the overall length. Rolling mill stand is an important part of a work stand, roll bearing chock and roller adjustment device is installed on the frame. Contacter le fournisseur »

In two high non reversing mills as two rolls which revolve continuously in same direction therefore smaller and less costly motive power can be used. However every time material is to be carried back over the top of the mill for again passing in through the rolls.

buy Rolling Mill Plant – Private Consultants is a leading importer of Hot Rolling Mill from Karachi,Pakistan. . Mill size: 12 inches 3 high with roughing stands.

PDF | In this paper, the spalling causes of backup rolls in a roughing mill of a hot strip rolling mill were investigated. The roughing mill withstood extreme service conditions with long service ...

Layout of a 4high rolling mill stand. Hot Mill Train A hotrolling mill train transforms steel slabs into flat strip by reducing the thickness, from some 200 millimetres to some two millimetres. Fig. 2 shows a typical hot strip mill train, consisting of a roughing mill (stands R1 .

Methods of calculation of load modes of roughing stand electric ... Jan 5, 2017 ... The paper provides analysis of load modes for electric drives of horizontal rolls installed at the continuous train of the widestrip hot rolling mill.

Kennametal metalworking catalogs for download. 1600 Technology Way, Latrobe PA, 15650

HOT STRIP MILL — HIGHEST PERFORMANCE FOR NEW AND EXISTING STEEL MILLS The demand for hot rolled strip is growing in multiple ways. To remain competitive, new and existing mills must meet this challenge in the best possible way. The production of hot strip is a key element of steel production.

New Trends in Hot Strip Mill Roughing Mills Orbi (ULg) Key words: Hot Strip Mill, Roughing Stands, Work Rolls, High Chromium Steel, .... material as a function of temperature while both samples are submitted to a .... just one reversing roughing mill combined with a vertical edger or a sizing press.

High Speed Steel Rolls for Rolling Mills CASE is manufacturing world class HSS Rolls specifically designed for rolling mills globally. We at CASE understand that for any modern rolling mill the impetus is given to mass production in particular with a keen emphasis on product quality.

FENN offers several standard Rolling Mill types; however custom machines can be designed to suit any application or production requirement. Standard Rolling Mill types include: Two High Generally used for hot or cold breakdown, rundown and finishing of bar, sheet or strip. A wide range of sizes with separating force capacities from 10,000 lbs. ( MT) to over 3,000,000 lbs. (1360 MT) are available.

world class rolls of the highest quality for over 100 years. The WHEMCO companies in Pennsylvania and Ohio, USA manufacture a full range of mill rolls – spun cast iron, cast steel and forged steel. Each of our roll manufacturing facilities has the expertise, equipment and experience to meet the most demanding rolling mill applications.

PDF | Two alloys grades for work rolls used in the roughing stand of Hot Strip Mill — high chromium steel (HCS) and semihighspeed steel (semiHSS), In this paper, the new semihighspeed steel ...

A wide variety of roughing roll options are available to you, such as pe, pvc. You can also choose from toilet tissue, stretch film, and holographic film. As well as from moisture proof, waterproof, and heatresistant. And whether roughing roll is food wrapping paper, or masking. There are 14,287 roughing roll suppliers, mainly located in Asia.

Advantages. By way of comparison, the rigidity of 4High/6High mills is governed by the relatively large size of their work rolls and backup rolls, which are supported by their necks in two separate housings connected by columns that elongate under load. Under rolling pressures, this design results in roll deflection and flattening,...

3 High Roughing Mill for Sale Mfr: Brightside [ UK ] Size: 620MM Dia x approx 1300MM Roll Face Drive Motor: 1250HP DC Roll Bearings: Roller Controls: Modern SCR Drive Mill Tables: Outgoing tilt table 220mm wide x 11000mm long Runout Table: 1500mm wide x 7000mm long This rolling mill is still installed and under power.

rollrolling mills appropriate for high precision rolling as the new rolling mill was selected. Outline and features of PFB rolling mill As the new rolling mill, two stands of the threeroll rolling mill were selected (Fig. 1). The major feature of the threeroll rolling ... rolling mills (8 stand roughing rolling mill, 4 .

wire mills, the rolling speeds are so high in many cases that it is no longer possible to use axial tapered roller bearings and axial spherical roller bearings. The axial bearings used in these cases are angular contact ball bearings or deep groove ball bearings. In backup .

The heart of the temper mill is the cold rolling mill stand which produces the temper pass. It will include electric powered drive motors and speed reduction gearing suited to the process desired. The design of the rolling mill can be a 2high or 4high (even 6high in some cases). The mill stand can be work roll driven or back up roll driven.

End Mills Whether you are rounding an edge, cutting a keyway or a multitude of other operations on your mill, MSC has the right end mills to keep your shop running smoothly. We stock a wide variety of carbide and highspeed steel end mill cutters to suit a myriad of applications.

Cutting tool experts since 1955, Regal sells the best in taps, drills, end mills, dies, gages and custom cutting tools for machining.

Rolling Mill Roughing Stand Drives129 Кб. Products SM38 Mill Spindles Rolling Mill Roughing Stand Drives A large Midwestern steel mill was experiencing excessive downtime due to frequentThe roughing mill work rolls require extremely high torque to compress/reduce 10" thick automotive quality heated steel slabs down to 1" 2" thick.

Dec 13, 2013· Work Roll change in a Hot Rolling Mill ( especially in a steel industry) E3: piston rod 20 mm forward in contrast to E2 (automatic release of the hook) Pos. E4: switch over to slow reverse: WRset run out of the mill stand Pos. E5: switch over to slow forward: WRset run back in the mill stand Pos. E6: lower position for top WR in mill stand Pos.