Iron sinter products are most popular in North America, Western Europe, and Domestic Market. You can ensure product safety by selecting from certified suppliers, including 15,022 with ISO9001, 3,778 with Other, and 2,088 with ISO14001 certification.

sintering of iron ore

The sintering mixture, necessary for iron ore sinter production, is composed of various kinds of iron ores, fluxes, recycled materials. The grain size of additives has to meet recycled raw materials and fuel. A new composition and new grain size of sintering mixture have been examined in a there are also plants demanding under 3 mm [8,9].

Sinter fines and lumps make up the bulk of the seaborne iron ore market, and are the products most frequently traded on a spot basis, so daily pricing is used for the key 62% Fe, 58% Fe and 65% Fe fines, and lump premium references.

Design and Supply together Perantech analyzes and manages the projects with an technocommercial approach so that the equipment configuration is based on the customer's requirements.

and iron ore. The objective of this paper is to develop an iron ore sintering bed model which takes the single particle into consideration and incorporates more information on individual particles in terms of the entire iron ore sintering bed. 2. Modeling Approach IntraParticle Combustion Model

The invention relates to a granulating method of iron ore concentrate sintering mixture, and belongs to the metallurgical field. The method solves the technical problem that the granulating method of the iron ore concentrate sintering mixture is provided, wherein, the granulating method can increase the quality of sintering minerals. The granulating method of the iron ore concentrate sintering ...

Iron Ore and Pellets. Vale is the world's biggest producer of iron ore and pellets, raw materials essential to the manufacture of steel. Iron ore is found in nature in the form of rocks, mixed with other elements. By means of various industrial processes incorporating cuttingedge technology, iron ore is processed and then sold to steel companies.

When iron ore deposits in the form of sinter are used for steel production, it is essential to monitor for homogenous sintering throughout the cake . The ARC thermal imager is our recommended solution.

Sintering. If the goethite types are unbalanced in a sinter blend, the result can be higher sintering fuel rate, due to the energy required to drive off excess moisture, as well as reduced productivity, due to excessive melt formation. The key is knowing what goethite textural types are present and in what proportions.

Media in category "Iron ore sinter" The following 10 files are in this category, out of 10 total.

Mar 19, 2019· The challenge. Aluminacontaining iron ores are major feed materials used in iron ore sintering in the Asia Pacific region. There are three main types of aluminacontaining iron ores and due to their unique properties they perform differently during the sintering process. An understanding of how they influence the sintering process is...

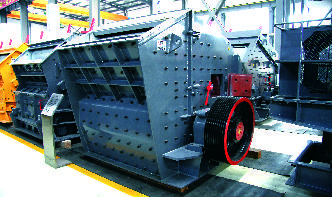

Smelting reduction processes are the latest development in pig iron production. of iron ore sinter and its behaviour during in india laboratory . Sintering Machine Sintering Machine . Belt Sintering Machine Our range of Belt Sintering Machine is mainly used to sinter iron ore, of Sintering Machine in Jaipur, Rajasthan, India. production

Keywords: Iron ore sintering, SFCA phases, Phase formation, In situ synchrotron XRD. During the iron ore sintering process, iron ore fines (< 6 mm) are mixed with limestone flux and coke breeze and heated to ~1300ºC. This results in partial melting of the mixture, and

Sintering is a process of agglomeration of iron ore fines. into a porous hard mass by INCIPIENT FUSION heat. generated within the mass itself TYPES OF SINTER: i) NON FLUXED OR ACID SINTERS: Those where no flux is present or is added in the ore. (ii) BASIC SINTER OR SELF FLUXING SINTER: .

Feb 16, 2017· Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming agents, and solid fuel (coke). The purpose of the sintering process is manufacturing a product with the suitable characteristics (thermal, mechanical, physical and chemical) to be fed to the blast furnace.

Influencing factor of sinter body strength and its effects on iron ore sintering indexes. The CSs of the blending ores only slightly affect the sintering time. The CS bottom limit of the blending ores is 310 N. When the CSs of the blending ores increase by 10%, the yield, productivity, and tumbler index increase by %, %, and %, respectively, and the solid fuel consumption decreases by %.