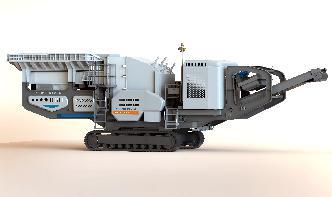

Smelting iron ore on a small scale iron ore on a small scale a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plant. Get Price

smelting iron ore on a small scale

The other two work towards making the ore easier to smelt – by transforming the ore into a reducible form, and increasing the surface area of the ore. Washing. Iron smelting might not be the cleanest of operations, yet washing does come into play at some point. Iron ore recovered from the ground generally comes covered in dirt.

small smelting plant for antimony ore prochoicelobbydayorg. small smelting plant for antimony ore 13 Feb 2014 small smelting gold plantsmelting iron ore on a small scale in Annoeullin France Crusher antimony smelting process Coal Crusher 123 Primary Copper Smelting 1231 General1 Copper ore is produced in 13 states In 1989 Arizona produced 60 ...

Hot blast iron smelting in the early 19th century: a reappraisal Paul Belford ABSTRACT: The introduction of hot blast was the most important development in early 19th century iron smelting. The conventional story of James Beaumont Nielson's 1828 patent has been widely accepted since the 1840s.

Iron ore, as mined, is a combination of iron with oxygen and various other unwanted substances, generally known as "gangue". The first metallurgical step is to reduce iron ore to metallic iron, a process which is mostly carried out in a blast furnace, using coke as both a fuel and reducing agent.

Jan 18, 2017· Gold miners have to smelt their gold in order to remove impurities resulting in pure gold. Most large scale gold miners send their ore to smelters with large equipment for the smelting process. Small scale miners still can do their own smelting using specialized kilns. Many people confuse gold smelting with melting.

In modern copper smelting, a reverberatory furnace is used. Concentrated ore and a flux, commonly limestone, are charged into the top, and molten matte—a compound of copper, iron, and sulfur—and slag are drawn out at the bottom. A second heat treatment, in another (converter) furnace, is necessary to remove the iron from the matte.

Smelting Enriched Bog Ore in a Low Shaft Bloomery.. Jonathan Thornton, Skip Williams and Shugar. Introduction: During the 3 rd International Symposium on Early Iron, held at Eindhoven, Holland, I participated in an iron smelting experiment along with Skip Williams, also of the United States, and with the occasional assistance of other casual helpers.

Follow my journey in to smelting iron from ore. Skip to content. Follow my journey in to smelting iron from ore. ... This way I have five very different surfaces for the five small garden sculptures. First the bulk of the outside scale was removed using the belt grinder. Several grades were used up to 240 grit and then the rest is done by hand.

Iron Smelting in Sudan: Experimental Archaeology at The Royal City of Meroe ... cate that iron production on a significant scale took place from at least the 7th–6th century B. ... remains of ore processing (the small pebble [<2 mm] and sand sized particles were judged too fine for effective smelt

Smelt reduction for iron and steel sector ... In the case of iron ore smelting the offgas from the furnace, consisting mainly of carbon monoxide and hydrogen, can be used for pre reduction of the other applications of the process, such as reclaiming of alloying metals from baghouse dust, the produced gas is utilised as a fuel the ...

offers 320 iron ore melting furnace products. About 84% of these are industrial furnace. A wide variety of iron ore melting furnace options are available .

The smelting furnace is a crafting station used for smelting ore into ingots. The furnace is crafted using a Workbench. The small furnace holds 1000 units of fuel and 24 units of ore. The large furnace carries 48 units of ore.

Towards an effective method for small iron smelting furnaces. Draft version of the article published in EuroREA, Fall 2011 Abstract: Few ancient processes are as mysterious as smelting ore into metallic iron. Just how, exactly, is this done? The exact processes used by the ancients are unknown, but modern experiments can suggest some possibilities.

Early Iron Smelting In • Central Africa More than 2,500 years ago the people near Lake Victoria began smelting iron in tall furnaces that produced a remarkable heat. The ... heating made the ore. brittle and easier to break into small pieces, which can be smelted more effectively. The piec

Small Scale Iron Ore Processing EquipmentSouth Africa. However, at the time of production, various operations have occurred in smallscale iron ore processing equipment due to inoperative operations or methods that are difficult to maintain. The following are matters needing attention in the maintenance of small iron ore processing equipment.

In short, centralized smelter works great for up to 2kSPM, maybe 3k. Anything above that i would at least use decentralized smelting but when going over 5kSPM it is a must to use onsite smelting. You even want to do double on site smelting at the really big scale, smelt copper and iron at the same location and craft at the same place.