Secondary technology may also be defined as Process Manufacturing Information Technology. Its goal is to use the information available in the optimum manner in all aspects of process, from design through training of operators to business decisions. The sugar industry is a data rich but information poor industry. For example, much work has been

sugar manufacturing process flow diagram

Sugar process steps. In food manufacturing – OPEX is the main cost lever of TCO Unloading cleaning Evaporation Crystal lization Centrifugation/ drying Cutting Milling Juice purification Water use. Processing efficiency. Energy efficiency. Milling. Sugar crystallization. Sugar centrifugals. Juice Purification. Cane preparation. %. %. %. %

The product from the process described so far is a raw sugar (Brown sugar) that can be used as is, or sent to a refinery to be converted to a white (refined) sugar. Sugar refining. The purpose of the refinery is to remove impurities from sugar crystals. The refinery accepts raw sugar as its feed material.

Mar 21, 2017· The sugar article mainly discussing about raw sugar definition, How to make raw sugar, raw sugar making process flow chart and specifications of raw sugar. The sugar article mainly discussing about raw sugar definition, How to make raw sugar, raw sugar making process flow chart and specifications of raw sugar ... Liquid Sugar Manufacturing ...

Raw Materials. The overall flavor of a soft drink depends on an intricate balance of sweetness, tartness, and acidity (pH). Acids add a sharpness to the background taste and enhance the thirstquenching experience by stimulating saliva flow. The most common acid in soft drinks is citric acid,...

= by product flow EVAPORATOR (T= 102 ... IGN SCHEMATIC BLOCK DIAGRAM OF SUGAR PROCESSING RS WEIGHING CANE WEIGHING MELTER MILLING STATION JUICE SCALE DEFEKATOR (pH = 11) SUGAR FROM CANE CANE RAW SUGAR WHITE SUGAR (FINAL PRODUCT) Final Molasse Final Molasse s. Title: Process flow Author: zunhaji

flow diagram for a commercial process. It may be that realizable starch content in mai ze is about 60 per cent. At its current price of,SOO per metric tonne, the material cost of starch works out to about,000 per metric tonne. Similarly, the practical range of sucrose content in

Major safety concerns are around the plug flow reactor: Free radical polymerization of ethylene to polyethylene is a highly exothermic reaction Converts gaseous ethylene into viscous polyethylene melt Thus many constraints must be taken for a process that aims to be effective and safe: reactor temperature (prevent unideal and

Refining Processing. Whether sugar comes from sugar beets or sugar cane, the purification process is similar for each plant, and the result is the same pure sucrose. One difference in processing between the two plants is that sugar beets are refined at a single facility, a sugar beet factory and sugar cane at two facilities: processing starts...

The process of shipping and refining cane sugar into granulated sugar. The process of beet harvesting, preparation, extraction, and purification for packaging and shipping.

production. The raw sugar refined in New Zealand today originates from Australia, Fiji, the ... thus reducing the amount of sugar dissolved in this process. The impure syrup is ... Bulk sugar (ship) Figure 1 Flow chart of the sugar refining process . VIFoodESugar5 Carbonatation

pineapple processing >>. The manufacturing process of pineapple products viz. Slices and Juice involves many steps and different subprocesses. Ripe and matured pineapples are washed, graded and peeled. Then they are crushed in the crusher to obtain juice. In case of slices, after peeling, uniform slices are made on the slicer.

Page 40 of 46 Penn State Berkey Creamery Process Flow 2014 Sherbet Product Sherbet Plant Penn State Berkey Creamery Ingredients Lowfat milk, skim milk, water, cream, sugar, dry corn syrup solids, stabilizer, liquid flavoring Packaging Packaged in quarts and 3gal bulk containers Storage and Distribution Stored and distributed under refrigeration ...

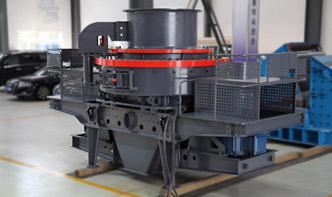

sugar industry process flow chart from crusher to production manufacturer in Shanghai, China. sugar industry process flow chart from crusher to production is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions.. stone crushing machine projectsugar industry process flow chart from crusher to production

Cake Manufacturing Process. Commercial baking companies turn out billions of products a day. The products must be uniform in size, shape and appearance in order to pass quality control tests, and this is achieved with the help of a largely automated process. Commercial mixers, fillers and ovens combine to process a high volume...

Over the past ten years, apart from some minor spikes in production, the Jamaican Sugar Industry has experienced decline in cane and sugar production. Cane and sugar production over this period averaged 1,805,871 and 163,387 tonnes respectively. For the 2010 crop the industry produced 121,806 tonnes sugar from tonnes cane.

Production of ENA (Extra Neutral Alcohol) and Ethanol (Absolute Alcohol) Then chemicals urea 25kg, enzyme 900 grams, sulphuric acid 20 Kg and biocide (Sodium meta bisulphite) 10 kg are added. The molasses and water is pumped in to the fermentor through diluter in .

Aug 02, 2012· Process Authority means an expert in the processes for controlling pathogenic microorganisms in food, and ad such, is qualified by training and experience to evaluate all of the aspects of your pathogen control measure, process time, temperature, type of equipment, and determine that your measures, if properly implemented, will control pathogens effectively.

Molasses is a viscous byproduct of of sugar cane process, grapes or sugar beets into sugar. First molasses was what was left after the sugar had been crystallized out once. When this was reboiled and more sugar crystallized out, the remaining syrup was second molasses. After a third time, the molasses was blackstrap molasses. Blackstrap is

The continuous flow manufacturing process is similar to the production line, but the products that are manufactured cannot be removed from the production line and stored, but require to have been through each process. For example, materials that are suited to continuous flow include chemicals, pharmaceuticals, and plastics.

Caramelization is a process of sugar turning brown when heat is applied. During this process, water is being removed from the sugar (Kamuf et al., 2003). The caramelization process can be conducted in open or closed vessels. The mixture obtained is cooled .

Caustic Soda Production and Manufacturing Process. ... The main production route in the US is via the diaphragm cell while the mercury and membrane cells are more dominant in Europe. There is environmental pressure on the older mercury route, with some bodies recommending a phaseout by 2010. ... allows a flow of brine from the anode to cathode ...