When LM Vertical Grinding Mill working, motor driven disc reducer rotating material air lock feeder from the feed inlet and on disc central, hot air from the inlet into the the disc rotation, the material under the effect of centrifugal force, to the disc edge to move through the annular groove on the disc by grinding roller compacted ...

vertical roller mill air meterial ratio

comparison of grinding efficiency between ball mills and vertical roller mills in coarse grinding Conference Paper (PDF Available) · June 2015 with 378 Reads How we measure 'reads'

Vertical roller mills are widely used in the concrete and mining fields, and are also used to process coal,lime and gypsum. These units can process both raw and recycled materials, while helping to reduce waste and preserve supplies of these materials. Capacity: 50250 t/

ECUTEC's Atlas Vertical Roller Mills have been developed for more efficient fine grinding of soft to mediumhard materials. The depth of the material bed on the grinding table is adjustable in order to control the retention time in the grinding zone. The ground material is entrained in the air stream which enters through tangential air ports in the base of the mill and is carried upwards to the classifier for the .

Grinding roller is the key grinding part and the core component of vertical roller mill. CHAENG manufactures vertical mill grinding roller, grinding table, roller hub, roller shell according to customers' drawings and requirements.

Vertical roller mill at present in domestic is mainly used for processing of coal, calcium carbonate and other minerals, mature production technology. In the production process, the failure rate is low, equipment intact rate can reach more than 98%, and high production efficiency. 3. the labor cost is low.

Especially the application ofvertical roller mill operation, greatly reduced slag cement grinding energy consumption and improve the grinding efficiency. 1, high grinding efficiency. Vertical mill material bed grinding principle of grinding material, 30% lower than the ball mill system. (ball mill sound energy and heat energy consumption)

Today the airswept vertical roller mill is the standard solution for coal grinding installations. And thanks to our continuous refinement of the ATOX coal mill over the years, today's leading airswept vertical roller mill is the compact ATOX. Offering high reliability, low installation costs and a .

The vertical mill rocker produced by SYMMEN METAL Casting has better wearresistant capability and good anticracking. We carry out the dressing and finishing by arc air gouging and shotblasting for the steel castings to guarantee the appearance quality.

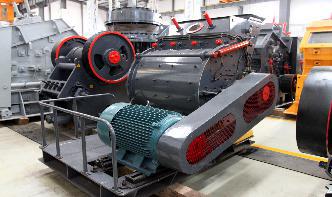

LM Vertical Roller Mill. LM series vertical milling machine, which is developed and launched by Zenith, sets medium crushing, drying, grinding, classifying and other functions as a whole, being the ideal equipment in the grinding industry.

LM series vertical roller mill grinding process is achieved by the motor drive mill and roller grinding of the material on the crushing, the motor through the reducer drive disc rotation, the material by the lock the wind feeder from the feed port in the center of the disc, while hot air from The air inlet enters the mill.

mill EP cooling air combustion air fuel stack O2 O2 O2 O2 F possible air leakage Air leakage may bring about an increase of both fuel consumption and fan power consumption. Air leakage occurred in kiln and preheater increases fuel consumption in order for heating leaked cold air up to process temperature. However, air leakage in EP and raw mill does not

Applications of Roller Mill LHG: Our roller mills are primarily used for superfine grinding of various dry powder materials. This kind of grinding mill is extensively used in industries like nonmetal mining, chemical engineering, building material production, metallurgic, new material .

In normal operation of the vertical mill, the vibration value of the mill should be strictly controlled within a reasonable range, and no more than /s should be allowed in an instant. 6. Air ...

LM fine vertical roller mill. New fine vertical roller mills is developed by our company, it create a particle size distribution with a sharper cut in comparison to cement milled in a traditional ball mill, the compact design allows it to dry, grind and classify, all within one piece .

Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the balltopowder ratio for ballmilling a new material? ... A vertical roller mill has been ...

Application of perfect mixing model for simulation of vertical roller mills H. Shahgholi1, K. Barani1* and M. Yaghobi2 ... product size leave the mill with the air, while the reject is fed back to the table for further comminution together with the fresh feed. The ...

LM vertical grinding mill with high cost performance ratio is the equipments that use for slag powder production, which has high efficient, low cost, complete functions, simple operation. Welcome to consult LM series vertical grinding mill and its spare parts online.

The material falls to grinding disc from the feed opening. ... the hot air from the nozzle take the fine powder to high effiency classsifer. The qualified powder are taken by the air to the powder collector to be collected, while the unqualified powder are sent back for regrinding. ... Therefore, cement vertical roller mill meets the national ...

The Factors Of LM Vertical Grinding Mill Price. The factors of vertical roller mill include the following aspects:First,the function of the function of the vertical roller mill more complete, the more direct impact on market prices will form due to the construction costs, material costs, the high cost of the, the ...

shows one of the world's largest vertical roller mills, the OK Mill 546, equipped with a conventional gear box with an installed power of 8 650 kW. 2 Concept and design of the drive systems The constant increase in the grinding capacity of vertical roller mills has defined the .