crushing and milling equipment, where abrasive wear of metal components in contact with the mineral constituents of the coal can affect the performance of the equipment, and can be a significant contributor to the maintenance costs. Erosive wear is associated with the impact of .

wear components for coal grinding

Raymond Grinding Parts Product Description It applies to all kinds of mineral preparation, pulverized coal preparation, such as raw ore, gypsum mine, coal and other materials, fine powder processing. We can provide all kinds of Raymond mill wear parts, such as roller, grinding ring, blade, etc., can also be based on the drawings provided by customers to create different materials products.

The portions of the grinding elements that are exposed to the pulverised coal/air mixture from the pulverised coal being suctioned off the bowl are also subjected to abrasion or erosion. Erosion is a velocity related wear component in which the force of erosion acts at an acute angle to the grinding face.

Components Of A Grinding Mill Components of Tubular Mill for Sale,Tubular Mill Parts Examining a typical cement clinker grinding mill, which can be considered to be representative of all tube mills, the ponents normally found as follows: coal grinding mill ponents coal processing plant. Oline Chat

Wodon wear plates are manufactured by welding one or multiple wear resistant layers on a medium or low carbon steel base plate. Wear Components Wodon wear plates are used to make many complex wear parts to be positioned in high wear places. Wodon wear plate can be welded and assembled into kinds of wear parts.

WearResistant Equipment and Grinding Media for the Mining Industry Magotteaux also design specific solutions for the dredging industry. ... of wear resistant components and grinding media through the company's... size reduction: cement, quarries, recycling and coalfired power plants. ... as low chromium (cast and forged), high chromium ...

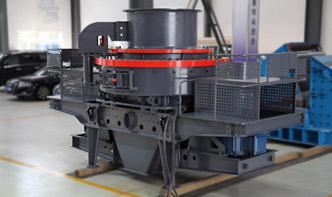

Coal crusher is a kind of new equipment designed for coal industry, coal crusher is Coal crusher is also known as coal crushing machine. jaw crusher content coal grinding denmark components of coal crusher machine in denmark ball mill, ball milling, ball, as a global leading manufacturer of products and services for the mining .

Major oil and natural gas companies rely on our Tungsten Carbide Drilling Components, Ceramic Pump Components, Tool Steel Wear Parts, Components and many other specialized oil wear parts. Our exceptional service, experienced personnel and trained machinists have given us an excellent reputation in many industries.

Loesche Grinding Technology for the Power Industry. 2 Loesche group history ... 2002 Coal grinding plant (LM D) for grinding wood ... • Wear life of the grinding parts is maximised through material selection and generous material wall thickness.

Preparation and coal dust burning plant contain several elements which participate in the preparation of coal dust that is made with six mills hammer and a fan [1]. Crushed coal mill is designed to dry and ground coal. Fan blades and hammers are used in grinding mill. .

An internal inspection should be completed to check the wear of grinding elements and classifier housings, vanes, and other internal components. Also, check for foreign matter that might be ...

High chromium white cast iron alloy used in coal grinding components is a material that may present different wear resistance depending on the thermal treatment used in its manufacturing.

Oct 21, 2018· Coal properties also influence the wear. Lining the parts of the pipes prone to wear with, for example, a urethane elastomer material provides abrasion resistance, as well as retarding the buildup of fines that can lead to blockage. Coal properties which are related to transfer line blockages are moisture content and clay minerals.

Custom Manufactured Tooling, Wear Parts and Specialty Components Elizabeth Carbide Components, an ISO 9001 Certified company, provides the highestquality Tungsten Carbide, Ceramic, Tool Steel Wear Parts, Specialty Components and other specialized parts to many industries throughout the world.

Dec 17, 2016· The choice of the coal grinding system depends on various aspects, like, size of coal lump, ash content, grindability, volatile components, abrasiveness, possibility of .

Top and bottom grinding rings; These large parts are cast of our J5 high chromium alloy i... Columbia Steel Wear Parts for EL Pulverizers by Columbia Steel Casting Co., Inc.. Superior wear part performance for EL 64, EL 70 and EL 76 coal pulverizers.

HC Series Grinding Mill widely applied in mineral grinding processing of metallurgy, ... coal gangue, wollastonite, slaked lime, zircon sand, bentonite, manganese, etc. ... HC mill has several patents of vertical pendulum structure, maintenancefree roller assembly, ...