Proper tension is achieved when the horizontal sag in the chain measures between 1/8 inch and 1/4 inch ( and mm) with drive belts in a fully opened position. The optional BEL 290T Spare Parts Maintenance Kit contains all of the parts necessary for maintaining the Uni‐Drive Conveyor System.

wiki conveyor belt drive system

Belt Conveyors. FEECO is the leading provider of custom conveying systems. We offer heavyduty belt conveyors for bulk handling applications. The right material handling system can add automation and fluidity to any application.

Interroll Drum Motors are mainly designed for use in belt conveyors and connected conveyor systems. Thanks to many years of experience in the belt conveyor sector, Interroll can offer a comprehensive range. Interroll Drum Motors enable the construction of maintenancefree, energyefficient conveyor belt .

Roller Conveyor. Belt Transfer Device BeltOverRoller Conveyor Center Pivot Conveyor Chain Transfer Device Conveyor Safe Walk DeSheeter ... Car Transfer Car Unit Load Downstacker Unit Load Former Visual Absolute Positioning System Stable Stack. Belt ... 10010 Conveyor Drive .

Jun 08, 2018· An installation consists of a drive system, a takeup system, additional components and the principal item, the conveyor belt. The height of fall of material being loaded to the belt should be kept as small as possible, the loading being in direct...

the loaded conveyor at the design velocity of the belt V, in fpm: (1) To determine the effective tension, T e, it is necessary to identify and evaluate each of the individual forces acting on the conveyor belt and contributing to the tension required to drive the belt at the driving pulley. T e .

pulleys and complete drive systems. The picture at left illustrates a shaft mounted reducer with a direct mount drive motor. Other drive options such as belt and chain systems are also available. Back stops can either be mounted internally to the reducer, or externally on the conveyor .

In addition to the added frustration to your drive, it can also wear out your tires faster. This same principle applies to metal conveyor belting. Every part of the conveyor, from the end rolls to the supporting rolls, must be level and parallel. If the conveyor is misaligned, the belt becomes difficult to track and it can stretch unevenly.

Very long belt conveyors transporting ore and other products often rely on conveyor belt idlers to form troughs in the belts to better contain the conveyed materials. Conveyor Systems A Summary. This guide provides a basic understanding of conveyor system varieties, considerations for use, their applications, and industrial uses.

A conveyor pulley is a mechanical device used to change the direction of the belt in a conveyor system, to drive the belt, and to tension the belt. Modern pulleys are made of rolled shells with flexible end disks and locking assemblies.

According be reduced, load among the drive drums can be to [22], energy savings as well as industrial uniformly distributed, easy to maintain, gears and productivity can be improved using adjustable speed bearings operational life can be increased and better drive (ASD). Modern belt conveyor system, which protection of the equipment.

We offer a number of conveyor controls for your powered conveyor system. The same controls offered in our powered conveyor belt systems are available as independent items, from pull cables to variable speed drives. PopOut Rollers.

Figure 2. Conveyor tracking with vision system The conveyor tracking system includes a trigger position at which a moving object is detected by a sensor connected as an input probe to the conveyor drive. When the object moving on the conveyor is detected, its exact position is captured.

Drive shafts are another common method used to move mechanical power around that is sometimes evaluated in comparison to chain drive; in particular belt drive vs chain drive vs shaft drive is a key design decision for most motorcycles. Drive shafts tend to be tougher and more reliable than chain drive, but the bevel gears have far more friction ...

the components are: Conveyor belt, motor, pulley and idlers, rollers, pneumatic cylinder, etc. The design of a belt conveyor system takes into account the followings: 1) Dimension, capacity and speed 2) Roller diameter 3) Industrial power and tension 4) Idler spacing 5) Pulley diameter 6) Motor 7) Type of drive unit

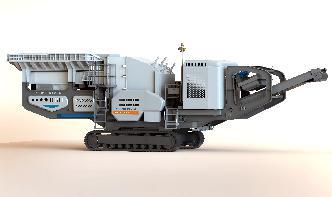

Conveyor drive systems, medium Moving diverse materials through tough conditions Whether transporting raw coal or metals at a mine, or bulk materials and finished goods at a port, conveyors endure abrasive contaminants and harsh elements.

Own working system activity carried on an element. Transmission of power from the drive member to the working member so provide the socalled transmission elements. [1,3,6] 2. Mechanical system to drive the conveyor belt Mechanical system to drive the conveyor belt is driven by the drive member of the .

Like the Tubulator, our airsupported belt conveyor has a totallyenclosed design that protects the environment from dust emissions and reduces any material losses to a minimum. Rather than using a pipe as the key containment method, the belt conveyor uses a formed pan to support the belt, with a fully flanged cover over it to make it dust tight.

Takeup adjustment is also important for any conveyor using belts as a means to power rollers, or belts themselves being the mover. With poortake up on beltdriven rollers, the belt may twist into the drive unit and cause damage, or at the least a noticeable decrease or complete loss of performance may occur.

The Conveyor Belt (ベルトコンべア Berutokon be a) is a gimmick that appears in the Sonic the Hedgehog series. It is a type of long, infinitely moving assemblies that can carry objects along their surfaces. Based on two or more rotating wheels with a long belt set on to move endlessly between them...