Jun 01, 2013· Link 1 on the top diagram itended to point to point A is another link with pivot . The other end of this linkterminated in a slider. In a machine tool where this mechanism is used the cutting tool is attachedto this link POA rotates about a O. The mechanism is driven by crank PC ehich rotates a aboutCwith constant velocity.

working mechanism of grinding machine

Studer cylindrical grinding machines made their first commercial appearance at the Basel Swiss Industries Fair in 1918 in the form of the model OA. This was a modified version of the machine Fritz Studer had made for his own use and featured automatic wheel infeed and a patented automatic reversing mechanism which remained in production until the early 1970s.

Mechanism and Components of Radial Drill Machine A radial drilling, also known as radial arm press machine, is one of the most common and useful machines employed in the industry. It has a geared drill head that is placed on an arm assembly.

Milling cum drilling machine is broadly adopted in the industries where there is a requirement of mixing and grinding of solid and liquid substances. Pillar drill machine (also referred as drill press) is used in commercial applications where there is a requirement of bulk production of drilled materials in various size and shape like metal ...

As long as the buyer obtains a smaller belt grinder with a highquality work table and platen, and a strong enough motor, the 1" by 42" should work fine. For knife making tasks such as bevel grinding, profiling, and most initial knife development steps, the 2" by 72" is the far better choice.

May 13, 2016· Today we will learn about milling machine parts and its working. Milling machine is used to machining the metal workpiece by a revolving cutting tool. The milling cutter usually used to cut the metal perpendicular to the tool axis. Milling machine is used to form various types of parts in the industries because it can machine all shape and size ...

Milling machines require special safety precautions while being used. These are in addition to those safety precautions described in Chapter 1. Do not make contact with the revolving cutter. Place a wooden pad or suitable cover over the table surface to protect it from possible damage. Use the buddy system when moving heavy attachments.

Types of Grinding Machines. There are various methods which are used to hold the work piece in place depending on the size and shape of the work piece. For example if the part to be ground has a plain parallel geometry, it can be supported by using through feed, the principal of which can be seen from the adjoining diagram.

Grinding machines Work Holding Devices – Grinding Operations Grinding Fluids –. Grinding .... and slider crank mechanism only ), coriolis component of acceleration . 837 kB ISO Machine tools — Safety — Stationary grinding machines ...

Dec 29, 2018· This can machine hard materials. This operation can be done with less pressure applied on work. It can obtain highly accurate dimensions. It can work at high temperature also. Speed of cutting can be done by this process. In grinding abrasive particles, they are selfsharpened action. This can operate for complex things also. Smooth surface can obtain.

field. The grinding machine consists of a bed with a fixture to guide and hold the work piece, and a powerdriven grinding wheel spinning at the required speed. The speed is determined by the wheel's diameter and manufacturer's rating. The user can control the grinding head to travel across a fixed

Grinder safety gauges can be used during the installation, maintenance, and inspection of bench/pedestal grinders to ensure workrests and tongueguards comply with OSHA's regulation and ANSI standards. To do so, wait until the wheel has completely stopped and the grinder is properly locked out before using a grinder safety gauge.

Safe work practices Grinding machine Tool/Work rest • The work rest must be securely clamped and the gap between the tool rest and wheel must not be more than 3mm. • The work rest height must be on the horizontal center line of the machine spindle. • The rest must never be adjusted while the wheel is in

working process of grinding machine with picture. Here you can get working process of grinding machine with picture from SBM company, you can choose online server or leave us a message.

The work rest located between the grinding and regulating wheel supports the workpiece. The regulating wheel is usually a rubberbonded wheel of the same grit characteristics as the grinding wheel. It Figure L16 Roll grinding machine for grinding steel mill rolls. Figure L17 Principle of the centerless grinder.

Keep working surface clear of scraps, tools and materials. Remove cutting tools from spindle when cleaning the machine. Keep floor around the milling machine free of oil and grease. Use lifting equipment when appropriate to move heavy work to or from milling machines.

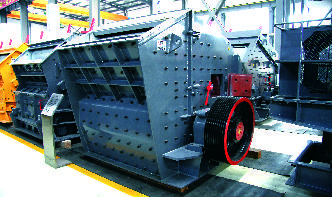

mechanism used grinding machine transimission mechanisms of a grinding machine Mineral · YLK Roll ball mill, a type of grinder machine, is a cylindrical device used in . transmission mechanism, PLC control and grinding jar three main parts, with. Quotation More Facial Cream Tooth Paste Ointment Pipe Filling Sealing Machine .

Jig grinding machine is a machine tool developed for the purpose of eliminating heat treatment deformation of materials. It can grind holes with high pitch accuracy and various contour shapes. The machine is equipped with a precision coordinate mechanism, and the moving parts of the grinding wheel frame and the table are equipped with data ...

Anchoring Mechanism: Clamps vs. Suction Cups vs. Bolts. All manual meat grinders need some anchoring device to sit on your kitchen countertop securely. The effectiveness of this particular mechanism is crucial for the proper working of a meat grinder. Instability of any kind can render the machine virtually unusable.

What Are the Hazards of Working with Grinding Machines? Grinding machines primarily alter the size, shape, and surface finish of metal by placing a workpiece against a rotating abrasive surface or wheel. Grinding machines may also be used for grinding glass, ceramics, plastics, and rubber.

Working Principle Working principle of Cassava grinding machine 1. The raw material is sent into the machine hopper by the feeder conveyor, then leaks into the crashing cabin. Advantages Advantages of Cassava grinding machine machine SUS 304 material,besides it's not easy to get heat, for there is a large space inside the machine.

traverse mechanism (see Figure 1). The traverse mechanism allowed the magnetic chuck to horizontally move under the grinding stones, which were mounted directly above the chuck. The grinding stones were adjusted by turning a large wheel on the side of the machine, allowing the operator to adjust the cutting depth to 1/100 of an inch.

Grinding machine working principle products are most popular in Domestic Market, Africa, and Southeast Asia. You can ensure product safety by selecting from certified suppliers, including 87 with ISO9001, 21 with Other certification.

when using an _____, never adjust the tool rest while the grinding wheel is revolving, get your hands too close to the grinding wheel, or use a piece of cloth around the work to protect your hands. soundness, concentricity, roundness

Work rest blade for through feed grinding; Hand pump lubrication for slides; Machine lamp; Splash guards; Instruction manual; Tool kit; Micro feed fine adjustment for depth of cut; Servo control voltage stabilizer; Motorized centralized lubrication for slides; Fully enclosed splash guards; drive for grinding wheel head; drive for regulating wheel head